When choosing an alumina crucible for your lab, several factors should be considered to ensure it meets your specific needs:

Material Purity: Alumina crucibles are typically made of high-purity alumina (Al2O3). Ensure that the crucible material is free from impurities that could contaminate your samples or experiments.

Temperature Resistance: Consider the maximum temperature that the crucible can withstand without deformation or failure. This is crucial for applications involving high-temperature processes such as melting metals or ceramics.

Chemical Compatibility: Check the compatibility of the alumina crucible in the USA with the chemicals and substances used in your experiments. Alumina is generally resistant to many chemicals, but it’s essential to verify compatibility with specific reagents.

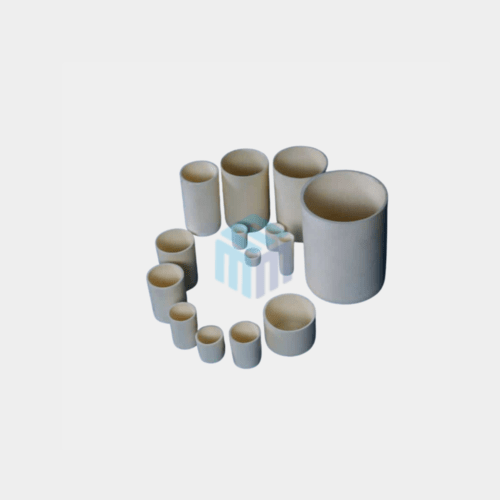

Size and Shape: Choose a crucible size and shape that accommodates the volume of material you will be working with. Consider the space available in your lab equipment, such as furnaces or heating elements.

Handling and Durability: Evaluate the crucible’s durability and ease of handling. Look for features such as reinforced rims or handles that make it easier to manipulate the crucible, especially when it’s hot.

Cost: Balance the quality and features of the alumina crucible with your budget. Higher purity and specialized features may come at a higher cost, so prioritize based on your experimental requirements.

Application Specifics: Consider any specific requirements of your experiments, such as thermal conductivity, thermal shock resistance, or electrical insulation properties. Choose an alumina crucible that aligns with these needs for optimal performance.

By carefully considering these factors, you can select an alumina crucible that is suitable for your lab’s applications and ensures reliable and consistent results. M-Kube Enterprise is a USA company catering customized laboratory products, laboratory consumables, and laboratory solutions in the USA, India, Australia, New Zealand, Singapore, Malaysia, South Korea, Dubai, Philippines, Indonesia, and Vietnam.