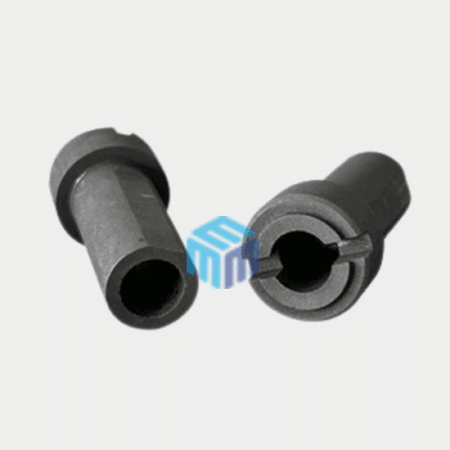

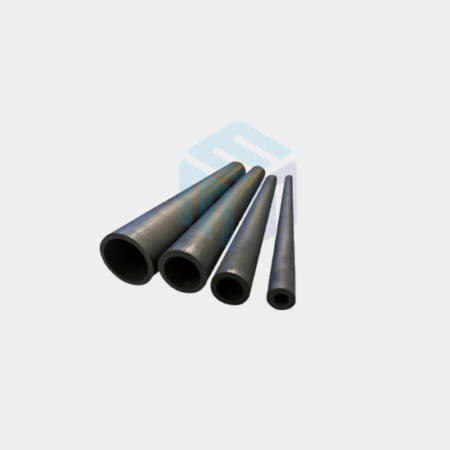

Graphite Trays

Inquiry NowProduct Description

Graphite trays are specialized trays or containers made from graphite materials. They are used in various industrial applications where high-temperature resistance, chemical inertness, and thermal stability are essential. Graphite trays are designed to withstand extreme conditions, making them valuable for specific processes and industries. Here are key features and applications of graphite trays:

Key Features:

- High-Temperature Resistance: Graphite trays can withstand extremely high temperatures, making them suitable for applications involving heat treatment, melting, and sintering processes.

- Chemical Inertness: Graphite is chemically inert and resistant to most chemicals, acids, and alkalis, making it ideal for applications where corrosion resistance is crucial.

- Thermal Stability: Graphite trays maintain their structural integrity and stability even under rapid temperature changes, making them suitable for thermal cycling applications.

- Low Thermal Expansion: Graphite has low thermal expansion, which minimizes the risk of cracking or warping in high-temperature environments.

Applications:

- Heat Treatment: Graphite trays are commonly used in heat treatment furnaces for processes like annealing, carburizing, and tempering of metals and alloys. They provide a stable and non-contaminating environment for the parts being treated.

- Sintering and Brazing: They are used in powder metallurgy processes for sintering metal and ceramic powders to create strong, durable components.

- Casting and Foundry: Graphite trays are employed in investment casting processes, where they hold the ceramic shell molds used to create precision castings.

- Glass Manufacturing: Graphite trays are used in glass production for holding and transporting glass products through various stages of the manufacturing process, including annealing and tempering.

- Chemical Processing: They find application in the chemical industry for holding and processing corrosive chemicals at high temperatures.

- Semiconductor Manufacturing: Graphite trays are used in the semiconductor industry for handling and processing wafers and other components in high-temperature and vacuum environments.

- Ceramic and Refractory Processing: They are used in the production of ceramics and refractory materials, where they can withstand the extreme temperatures of the manufacturing process.

- Metallurgy: Graphite trays are used in metallurgical applications for the smelting, refining, and alloying of metals.

- Solar and Photovoltaic Industry: They are used for the production of photovoltaic cells, where high-temperature processes are involved.

- Environmental Testing: Graphite trays are employed in high-temperature environmental testing for materials and components.

Graphite trays are available in various sizes and shapes to suit different applications, and they can be customized to meet specific requirements, such as tray dimensions and configurations. Proper selection and handling are crucial to ensure optimal performance and longevity in various industrial applications.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.