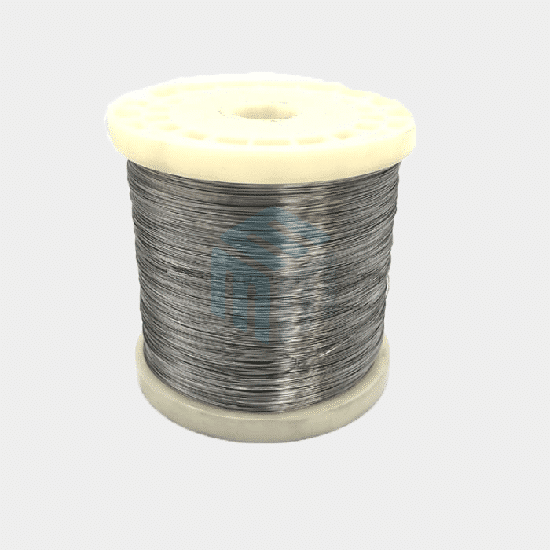

Titanium Wire

Inquiry NowProduct Description

General information

Titanium wires possess the properties of titanium therefore have features such resistance to corrosion, robustness, low density, non-magnetic, non-toxic, high mechanical strength etc. and are easy to process.

Titanium wires are made from titanium rods. The process comprises of drawing the rods into wires of different diameters and are eventually cut into different lengths. Titanium wires are strong with extreme ductility and elasticity. Two types of surfaces are available for titanium wires – pickling and bright surfaces.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at [email protected] or call us at +1-858-605-1447 to discuss your projects.

We also provide Titanium Crucibles, Rods and Tubes, and Titanium substrates.

Key properties

- Melting point 1660 °C

- Boiling point 3290 °C

- Low Density

- High material strength

- Excellent Corrosion Resistance

- Good heat resistance

- Non-magnetic

- Non-toxic

- Good thermal qualities

- Low elastic modulus

Application

Titanium wires possess the qualities of the metal which is beneficial for several applications, they are used: –

- As titanium mesh

- In military

- For welding

- For accessories like earrings, headwear

- In medical field

- Laboratory appliances

- For electronic devices such as 3D printer