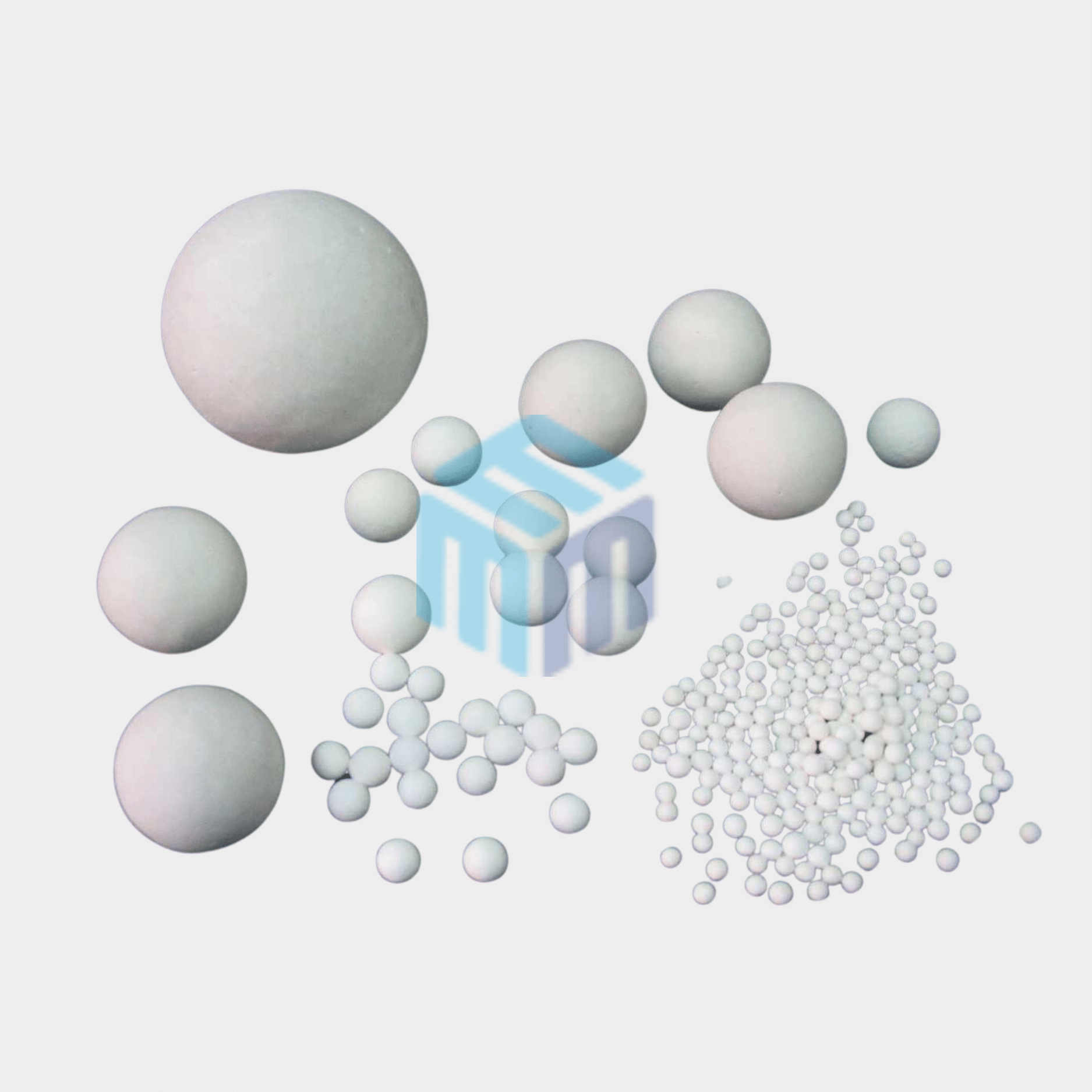

Alumina Grinding Media

Inquiry NowProduct Description

Alumina grinding media, also known as alumina balls or ceramic beads, are high-density and ultra-hard ceramic grinding balls made primarily from alumina (aluminum oxide, Al2O3). They are widely used in various industrial applications for the purpose of grinding, milling, and dispersing materials. Alumina grinding media offer several advantages, including high wear resistance, chemical stability, and low contamination. Here are key features and applications of alumina grinding media:

Key Features:

- High Hardness: Alumina grinding media are exceptionally hard and can effectively grind or mill materials that are harder than themselves.

- Wear Resistance: They exhibit excellent wear resistance, which results in longer service life and minimal contamination of the materials being processed.

- Chemical Inertness: Alumina is chemically inert and is compatible with a wide range of chemicals and solvents, making it suitable for various applications.

- High Purity: High-purity alumina grinding media are available for applications where product contamination is a concern.

- Low Density: Alumina grinding media have low density, which can lead to reduced grinding energy consumption.

Applications:

- Ball Milling: Alumina grinding media are commonly used in ball mills and stirred mills for the purpose of grinding and dispersing materials. They are utilized in industries such as ceramics, paint, pigments, and pharmaceuticals.

- Ceramic Industry: Alumina grinding media are used for grinding ceramic raw materials, glazes, and pigments during the production of ceramic tiles, sanitaryware, and pottery.

- Mining and Minerals Processing: In the mining industry, alumina balls are used in grinding mills for the comminution of ores, minerals, and precious metals.

- Paints and Coatings: They are employed in the production of paints, inks, and coatings for dispersion and milling processes, ensuring fine particle size and uniform distribution of pigments.

- Pharmaceuticals: Alumina grinding media are used in pharmaceutical manufacturing for grinding and processing active pharmaceutical ingredients (APIs), excipients, and drug formulations.

- Chemical Processing: They find applications in chemical processes for grinding and milling chemicals and catalysts.

- Food Industry: Alumina balls are used in food processing for grinding and dispersing food ingredients, such as cocoa, spices, and flavorings.

- Cosmetics: In the cosmetic industry, alumina grinding media are used for processing and milling cosmetic ingredients and formulations.

- Environmental Remediation: They are used in soil and sediment sample preparation for environmental analysis and remediation.

- High-Tech Materials: In the production of advanced materials, such as ceramics, advanced composites, and electronic materials, alumina grinding media plays a critical role in achieving the desired material properties.

Alumina grinding media come in various sizes and shapes, and their selection depends on the specific requirements of the application, such as the particle size, the material being processed, and the type of mill or equipment used. The choice of alumina grinding media can significantly impact the efficiency and quality of the grinding or milling process.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at [email protected] or call us at +1-858-605-1447 to discuss your projects.