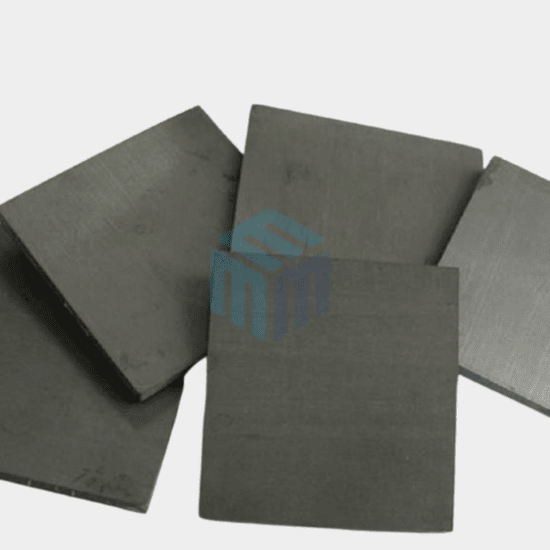

Silicon carbide (SiC) is a versatile material with excellent properties that make it suitable for various industrial, electronic, and structural applications.

Here are the key properties, uses, and maintenance tips for silicon carbide:

Properties of Silicon Carbide:

- High-Temperature Resistance: Silicon carbide can withstand very high temperatures, typically up to around 1600°C (2912°F) in air and even higher temperatures in inert or vacuum environments. This makes it ideal for high-temperature applications such as heating elements, furnace components, and thermal barriers.

- Chemical Inertness: Silicon carbide is chemically inert and resistant to corrosion by most acids, alkalis, and corrosive chemicals. It maintains its integrity and properties even in harsh chemical environments, making it suitable for chemical processing and industrial applications.

- Mechanical Strength: Silicon carbide has excellent mechanical strength and hardness, making it highly resistant to mechanical wear, abrasion, and impact. It is used in structural components, cutting tools, abrasives, and wear-resistant coatings.

- Electrical Conductivity: Silicon carbide can be either conductive or semi-conductive depending on its composition and doping. It is used in electronic components such as semiconductor devices, power electronics, and high-temperature sensors.

- Thermal Conductivity: Silicon carbide has high thermal conductivity, allowing for efficient heat transfer and thermal management. It is used in heat sinks, thermal interface materials, and heat exchangers for electronic and thermal management applications.

- Low Thermal Expansion: Silicon carbide has a low coefficient of thermal expansion, meaning it experiences minimal dimensional changes with temperature variations. This property helps prevent thermal stress-induced cracking.

- Abrasive Properties: Silicon carbide is widely used as an abrasive material in grinding, cutting, and polishing applications. It is used in abrasive wheels, sandpapers, and cutting tools for metalworking, ceramics, and stone processing.

Uses of Silicon Carbide:

- High-Temperature Applications: Silicon carbide is used in high-temperature applications such as heating elements, furnace linings, crucibles, and refractory materials for industries such as metallurgy, ceramics, and glass manufacturing.

- Electronic Components: Silicon carbide is used in electronic components and devices such as diodes, transistors, thyristors, and power modules for high-temperature, high-power, and high-frequency applications.

- Structural Components: Silicon carbide is used in structural components such as bearings, seals, nozzles, and turbine parts in aerospace, automotive, and industrial equipment where high mechanical strength and wear resistance are required.

- Abrasive Tools: Silicon carbide is used as an abrasive material in grinding wheels, cutting tools, sandpapers, and abrasive compounds for metalworking, sharpening, polishing, and surface finishing applications.

- Thermal Management: Silicon carbide is used in heat sinks, thermal interface materials, and heat exchangers for electronic devices and systems requiring efficient thermal conductivity and heat dissipation.

Maintenance Tips for Silicon Carbide Components:

- Cleaning: Clean silicon carbide components regularly to remove debris, residues, and contaminants that can affect their performance. Use appropriate cleaning methods and avoid harsh chemicals that could damage the material.

- Avoid Mechanical Stress: Handle silicon carbide components with care to avoid mechanical stress, impact, or damage. Follow recommended handling procedures and avoid dropping or mishandling the components.

- Inspect for Damage: Periodically inspect silicon carbide components for signs of wear, damage, or degradation. Check for cracks, chips, or surface abnormalities that may indicate structural issues.

- Temperature Control: Maintain proper temperature control when using silicon carbide components in high-temperature applications. Avoid rapid temperature changes or thermal shock that could lead to thermal stress and cracking.

- Storage: Store silicon carbide components in a clean, dry environment to prevent contamination, moisture absorption, and damage. Use protective packaging or storage racks to avoid physical damage during storage and handling.

By understanding the properties, uses, and maintenance tips for silicon carbide, you can ensure the optimal performance, longevity, and reliability of silicon carbide components in various industrial, electronic, and structural applications.

M-Kube Enterprise is a USA company catering customized laboratory products, laboratory consumables, and laboratory solutions in the USA, India, Australia, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.