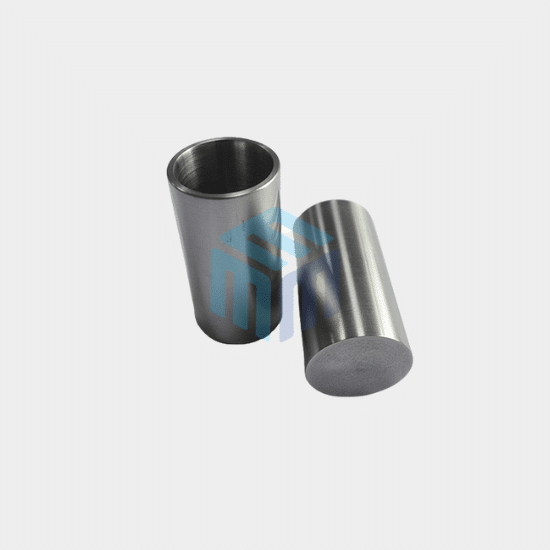

Molybdenum crucibles offer several features and advantages that make them suitable for high-temperature applications in industries such as metallurgy, electronics, and research laboratories. Here are the key features and advantages of molybdenum crucibles:

- High Melting Point: Molybdenum has a high melting point of approximately 2620 °C (4748 °F), making molybdenum crucibles capable of withstanding the extremely high temperatures required for melting refractory metals, ceramics, and alloys.

- Chemical Resistance: Molybdenum is resistant to corrosion by many acids, alkalis, and molten metals, making molybdenum crucibles suitable for handling corrosive materials and reactive substances in various industrial processes.

- Thermal Conductivity: Molybdenum has good thermal conductivity, allowing for efficient heat transfer within the crucible. This property is beneficial for uniform heating and temperature distribution during high-temperature processes such as melting and annealing.

- Low Thermal Expansion: Molybdenum has a relatively low coefficient of thermal expansion, which means molybdenum crucibles experience minimal dimensional changes with temperature variations. This property helps reduce the risk of thermal stress-induced cracking.

- High Strength and Durability: Molybdenum crucibles exhibit high strength and durability, enabling them to withstand mechanical stress, thermal cycling, and rapid temperature changes without deformation or failure. This characteristic contributes to their long service life.

- Refractory Properties: Molybdenum is classified as a refractory metal, along with tungsten, due to its ability to withstand high temperatures without softening or melting. Molybdenum crucibles are therefore used in high-temperature applications such as vacuum furnaces and plasma processes.

- Compatibility with Vacuum Environments: Molybdenum is compatible with high vacuum environments, making molybdenum crucibles suitable for processes that require vacuum or inert gas atmospheres, such as thin-film deposition, sintering, and heat treatment.

- Ease of Machining: Molybdenum is relatively easy to machine and shape, allowing for the production of customized crucible designs to meet specific application requirements.

- Versatility: Molybdenum crucibles find applications in a wide range of industries, including aerospace, electronics, metallurgy, and research laboratories, where high-temperature resistance, chemical inertness, and thermal stability are essential.

Overall, the features and advantages of molybdenum crucibles make them a valuable choice for demanding applications that involve high temperatures, corrosive environments, and stringent performance requirements.

M-Kube Enterprise is a USA company catering customized laboratory products, laboratory consumables, and laboratory solutions in the USA, India, Australia, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.