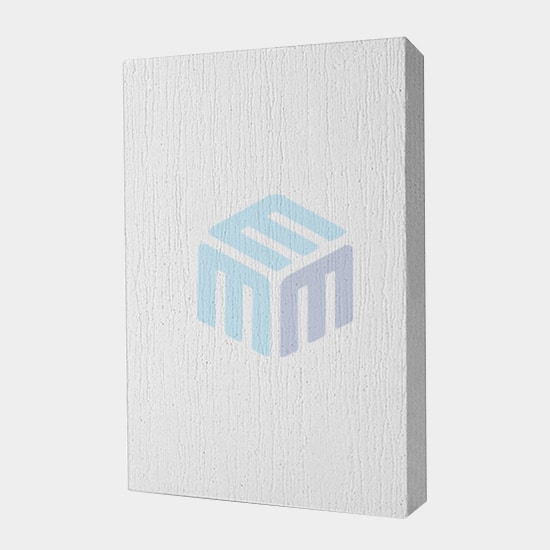

Ceramic Fiber Board

Inquiry NowProduct Description

Ceramic Fiber Board is made by vacuum forming process. According to different temperature grades, refractory fiber product may add proper organic and inorganic additives into polycrystalline mullite fiber, high alumina fiber, zirconic fiber, and aluminum silicate fiber, etc. by use of vacuum moulding methods, to manufacture all kinds of products with different temperature grades: 1000 degree, 1260 degree, 1400 degree, 1500 degree, 1600 degree and 1700 degree. Its varieties include two classes: fiber plate and fiber special-shaped product.

Characteristic:

| 1. Low density and low thermal conductivity |

| 2. Shorter heat up and cool down time |

| 3. Resilience and resistance to thermal shock |

| 4. Greater mechanical strength |

| 5. Even density, thickness |

| 6. Flexible and easy to cut or install |

| 7. Costs Saving |

Application:

| 1. Various High Temperature Furnace Lining and backing |

| 2. The heat insulation of back lining of industrial kilns; |

| 3. The liner of the hot side of ceramic kiln, mechanical and metallurgical heat furnace, heat treatment furnace and other industrial kilns; |

| 4. High-temperature fire stopping and muffle; |

| 5. Heat insulation materials such as kiln car, kiln door, and expansion gap, etc. |

| 6. Glass kiln heat insulation. |

Specifications:

| AYB-1000/300 | AYB-1260/300 | AYB-1400/300 | AYB-1500/300 | AYB-1600/400 | AYB-1700/400 | |

| Classification Temperature Continuous Temperature | 1000℃ 1818°F 900℃ 1636°F | 1260℃ 2300°F 1100℃ 2012°F | 1400℃ 2545°F 1200℃ 2192°F | 1500℃ 2732°F 1300℃ 2372°F | 1600℃ 2912°F 1500℃ 2732°F | 1700℃ 3092°F 1600-1650℃ 2912-3000°F |

| Density Other Density From 200 to 600 Kg/m3 available upon request | 300Kg/m3 18lbs/ft³ | 300Kg/m318lbs/ft³ | 300Kg/m318lbs/ft³ | 300Kg/m318lbs/ft³ | 400Kg/m325lbs/ft³ | 400Kg/m325lbs/ft³ |

| Linear Shrinkage (% ,°C x 24 hrs) | 1.3 (900) | 1.1 (1100) | 1.6 (1200) | <2 (1300) | <2 (1500) | <2 (1600) |

| Thermal Conductivity Kcal/mh°C (W/mk), ASTMC201 | 250kg/m3 | 250kg/m3 | 200kg/m3 | 200kg/m3 | 200kg/m3 | 200kg/m3 |

| Mean 400 °C | 0.08 | 0.09 | ||||

| Mean 600 °C | 0.13 | 0.14 | 0.10 | 0.09 | 0.12 | |

| Mean 800 °C | 0.02 | 0.18 | 0.14 | 0.13 | 0.16 | 0.11 |

| Mean 1000 °C | 0.20 | 0.18 | 0.21 | 0.16 | ||

| Chemical Compositon (%) | ||||||

| Al2O3 | 40.1 | 44 | 52 | 52 | 64 | 75 |

| SiO2 | 54.3 | 54 | 47 | 47 | 35 | 24.5 |

| Available size | 1000 x 600 x THK From 20 to 150mm Standard Board Size 1000 x 500 x THK From 20 to 150mm Standard Board Size 600 x 400 x THK From 20 to 150mm Standard Board Size Other board Sizes and thickness available upon request. | |||||

| Note: Data are average results of standard tests which are subject to variation, don’t show the guarantee datas of product quality because of fluctuating within certain range and should not be used as specification. | ||||||