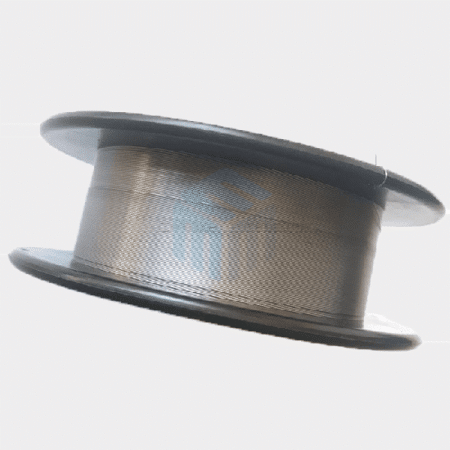

Tantalum Rods and Tubes

Inquiry NowProduct Description

Tantalum rods and tubes are made up of tantalum sheets that go through extrusion, pipe reduction, or deep drawing to manufacture welded and seamless pipes. Large diameter ingots are cold rolled into smaller diameters. These are intermediately annealed, recrystallising the metal, and this whole process is then repeated. This process makes sure that there is no inconsistency found in Tantalum rods.

Tantalum rods and tubes are very hard. Tantalum is a rare metal that is chemically an inert as well as a stable element. Tantalum rods and tubes are ductile and can be made into filaments or foils. It has a low thermal expansion coefficient.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.

We also provide Tantalum Wires, Tantalum Crucibles, and Tantalum substrates.

Key properties

- High melting point 3,017 °C

- High boiling point 5,458 °C

- Material strength

- Chemically stable

- Chemically inert

- High density

- High resistance to corrosion

- Ductile

Application

Tantalum rods and tubes are tough and have a high temperature resistance, and corrosion resistance. They are used: –

- For chemical reaction containers

- For producing thermocouple

- For cutting tantalum jewellery

- To produce tantalum wires, fasteners and specific shaped parts

- In aeronautics industries

- To produce tantalum electrodes

Frequently Asked Questions:

Can Tantalum Bars and Rods be easily machined or welded?

Yes, tantalum bars and rods can be machined and welded, though they require specialized techniques. Due to the hardness and high melting point of high purity tantalum rod materials, machining should be performed using carbide tools at low speeds. Welding is typically done in an inert atmosphere like argon to avoid oxidation. Reputable tantalum rod suppliers often provide handling and fabrication guidance for industrial applications.

How is Tantalum Bar or Rod used in the electronics industry?

Tantalum bars and rods play a vital role in the electronics industry, especially in the manufacturing of capacitors, vacuum electronics, and thin-film resistors. Their excellent conductivity and resistance to corrosion make them ideal for high-performance circuits. Many tantalum rod manufacturers supply materials specifically designed for use in electronic components requiring durability and precision.

Are TA0005 Tantalum Bars and Rods available in custom sizes?

Yes, TA0005-grade tantalum bars and rods are available in various custom sizes and shapes to meet exact design specifications. Whether you’re sourcing for aerospace, research, or electronics, tantalum rod suppliers typically offer precision-cut solutions with options for surface finish and dimensional tolerances.

What temperatures can tantalum rods withstand?

Tantalum rods are known for their exceptional heat resistance, operating safely at temperatures up to 3,000°C in vacuum or inert gas environments. This performance makes high purity tantalum rods ideal for high-temperature furnaces, space applications, and advanced material research.

Are tantalum rods corrosion-resistant?

Yes, tantalum rods are extremely corrosion-resistant, especially in acidic environments like nitric, sulfuric, and hydrochloric acid. This property is one reason why industries rely on tantalum rod manufacturers when sourcing materials for chemical processing equipment, heat exchangers, and lab-grade applications.