Quartz Customization Applications

Inquiry NowProduct Description

Quartz is a versatile material that can be customized for various applications due to its excellent optical, electrical, and mechanical properties. Here are some common applications where customization in quartz is essential:

- Optical Components:

- Lenses: Quartz lenses can be customized to meet specific optical requirements, such as focal length, numerical aperture, and coatings. They find applications in imaging, laser systems, and scientific instruments.

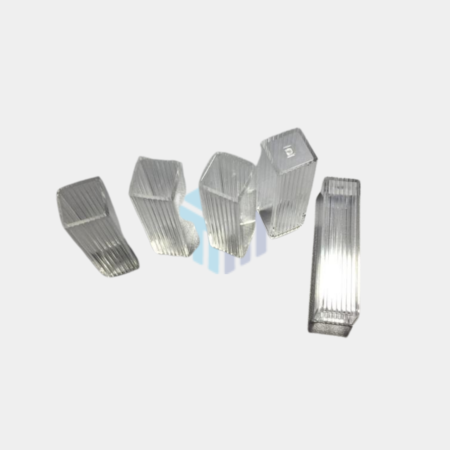

- Prisms: Custom quartz prisms can be designed with specific angles, sizes, and coatings for tasks like beam steering, dispersion, and polarization control.

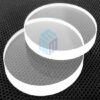

- Windows: Custom quartz windows are used for optical protection and transmission in harsh environments, and they can be tailored to fit various optical systems.

- Quartz Crucibles: In materials processing, quartz crucibles can be customized in terms of size, shape, and purity to accommodate different types of crystal growth processes, including semiconductor manufacturing and research.

- Quartz Tubing: Customized quartz tubing is used in applications like chemical vapor deposition (CVD), where precise dimensions and purity are critical for the growth of thin films and coatings.

- Quartz Wafers: In the semiconductor industry, custom quartz wafers with specific dimensions, surface finishes, and tolerances are used for various processes, including lithography, etching, and inspection.

- Quartz Sensors: Quartz sensors, such as quartz crystal microbalances (QCM), can be customized to detect specific analytes or substances by modifying the sensor’s surface chemistry or design.

- Quartz Oscillators: Custom quartz crystal oscillators are used in various electronic devices, including precision timing, frequency control, and signal processing applications. These oscillators can be tailored to meet specific frequency and stability requirements.

- Quartz Resonators: Customized quartz resonators, like quartz tuning forks, are used in sensors, oscillators, and analytical instruments. Their dimensions and resonance frequencies can be customized for specific applications.

- Quartz Tubes and Rods: Custom quartz tubes and rods are employed in heating and furnace applications, with the possibility of tailoring their dimensions, wall thickness, and end configurations.

- Quartz Filters: Custom quartz filters can be designed to achieve specific spectral characteristics, such as wavelength selection and light transmission. They are used in optical and spectroscopic systems.

- Quartz Crystal Microbalance (QCM) Sensors: QCM sensors can be customized with coatings or functionalization to make them selective for specific analytes in applications like chemical sensing and biosensing.

- Customized Quartz Parts: In research and industrial settings, custom quartz parts can be created to meet unique requirements in various applications, including scientific instruments, optics, and research equipment.

To achieve customization in quartz applications, it’s important to work with manufacturers or suppliers who specialize in precision quartz fabrication. They can help design and produce quartz components to meet specific material properties, geometrical dimensions, surface finishes, and functional requirements, ensuring that the final product aligns with the intended application.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.