Alumina Crucibles

Inquiry NowProduct Description

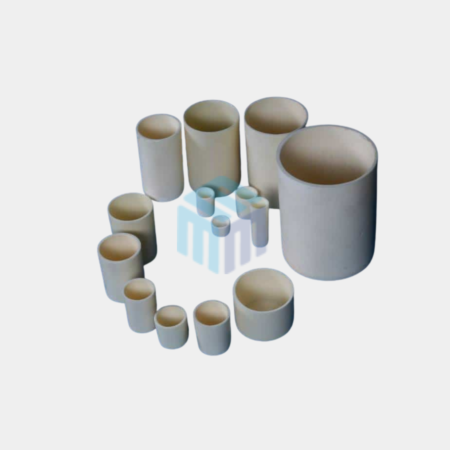

Alumina Crucibles – High-Purity Ceramic Crucibles for Extreme Temperatures

M-Kube Enterprise supplies high-purity alumina crucibles made from premium aluminum oxide (Al₂O₃), delivering unmatched thermal performance and chemical resistance. Designed for high-temperature applications, these ceramic crucibles are essential in materials testing, analytical labs, metallurgy, and research environments throughout the United States.

Whether you’re melting metals, conducting calcination, or preparing samples, our alumina ceramic crucibles offer the purity, durability, and precision your process demands.

Standard and Custom Alumina Crucibles for Lab and Industrial Use

We offer a wide range of standard alumina crucibles—including cylindrical, conical, rectangular, and boat-shaped variants—along with custom crucible solutions tailored to your specifications.

Our customization application capabilities include:

- Custom shapes and wall thicknesses

- Open- or closed-top options, with or without lids

- Polishing, labeling, and engraving

- Support for small-batch R&D and large-volume manufacturing

- Precision tolerances up to ±0.05mm

At M-Kube Enterprise, we work closely with clients in the USA to ensure reliable sourcing and custom engineering for their ceramic requirements. Some of the standard dimensions are

| S.No | Product Code | Description |

| 1 | Al-CoC-027-022-015-00003-L | 99.8% Alumina Conical crucible + Lid, Top OD 27 mm, Bottom OD 22 mm, H 15 mm (5 ml) |

| 2 | Al-CoC-027-022-015-00003 | 99.8% Alumina Conical crucible, Top OD 27 mm, Bottom OD 22 mm, H 15 mm (5 ml) |

| 3 | Al-CoC-031-019-029-00001 | 99% Alumina Conical Crucible, Top OD 31 mm, Bottom OD 19 mm, H 29 mm |

| 4 | Al-CoC-031-019-029-00001-OL | 99% Alumina Conical Crucible LID ONLY Top OD 31 mm, Bottom OD 19 mm, H 29 mm |

| 5 | Al-CoC-040-022-040-00002 | 99% Alumina Conical Crucible, Top OD 40 mm, Bottom OD 22 mm, H 40 mm (25 ml) |

| 6 | Al-CyC-013-000-025-00014-L | 99.7% Alumina Cylindrical crucible + Lid OD 13 mm, H 25 mm (1-2 ml) |

| 7 | Al-CyC-013-000-025-00014 | 99.7% Alumina Cylindrical crucible OD 13 mm, H 25 mm (1-2 ml) |

| 8 | Al-CyC-018-015-025-00023 | 99.8% Alumina cylindrical crucible OD 18mm ID 15mm Height 25mm |

| 9 | Al-CyC-016-000-050-00006 | 99% Alumina Cylindrical Crucible OD 16 mm, H 50 mm (5 ml) |

| 10 | Al-CyC-016-000-056-00007 | 99% Alumina Cylindrical Crucible OD 16 mm, H 56 mm (6 ml) |

| 11 | Al-CyC-019-000-035-00008 | 99% Alumina Cylindrical Crucible OD 19 mm, H 35 mm (6 ml) |

| 12 | Al-CyC-022-000-020-00001 | 99% Alumina Cylindrical Crucible, OD 22 mm, H 20 mm (5 ml) |

| 13 | Al-CyC-022-000-020-00003-L | 99.8% Alumina Cylindrical crucible + Lid OD 22 mm, H 20 mm (1-2 ml) |

| 14 | Al-CyC-022-000-020-00003 | 99.8% Alumina Cylindrical Crucible OD 22 mm, H 20 mm (1-2 ml) |

| 15 | Al-CyC-016-000-044-00019 | 99% Alumina Cylindrical Crucible OD 16 mm, H 44 mm (4 ml) |

| 16 | ||

| 17 | Al-CyC-019-000-035-00018-L | 99% Alumina Cylindrical Crucible+Lid OD 19 mm, H 35 mm (6 ml) |

| 18 | Al-CyC-022-000-027-00005 | 99.8% Alumina Cylindrical Crucible OD 22 mm, H 27 mm (7 ml) |

| 19 | Al-CyC-022-000-027-00005-L | 99.8% Alumina Cylindrical Crucible+Lid OD 22 mm, H 27 mm (7 ml) |

| 20 | Al-CyC-030-000-070-00002 | 99% Alumina Cylindrical Crucible, OD 30 mm, H 70 mm (45 ml) |

| 21 | Al-CyC-035-000-065-00004 | 99% Alumina Cylindrical Crucible OD 35 mm, H 65 mm (42 ml) |

| 22 | Al-CyC-036-000-135-00011 | 99.7% Alumina Cylindrical Crucible OD 36 mm, H 135 mm |

| 23 | Al-CyC-046-000-030-00021 | 95% Alumina Cylindrical Crucible with 3 partition OD 46mm Height 30mm |

| 24 | Al-CyC-049-000-145-00022 | 99.8% Alumina cylindrical crucible OD 49mm Height 145mm with 4.3mm wall thickness |

| 25 | Al-CyC-056-000-063-00020 | 99.8% Alumina Cylindrical Crucible OD 56 mm, H 63 mm (ID 50mm, IH 60mm) |

| 26 | Al-CyC-060-000-055-00017 | 99.7% Alumina Cylindrical crucible OD 60 mm, H 55 mm (120 ml) – 3mm Thickness |

| 27 | Al-CyC-060-000-055-00015 | 99.7% Alumina Cylindrical crucible OD 60 mm, H 55 mm (120 ml) |

| 28 | Al-CyC-060-000-060-00009 | 99.8% Alumina Cylindrical Crucible OD 60 mm, H 60 mm (130 ml) |

| 29 | Al-CyC-080-000-080-00012 | 99.8% Alumina Cylindrical Crucible OD 80 mm, H 80 mm (250 ml) |

| 30 | Al-CyC-095-000-095-00013 | 99.7% Alumina Cylindrical Crucible OD 95 mm, H 95 mm (450 ml) |

| 31 | Al-CyC-100-000-085-00010 | 99.7% Alumina Cylindrical Crucible OD 100 mm, H 085 mm (530 ml) |

| 32 | Al-CyC-150-000-150-0016 | 99.7% Alumina Cylindrical Crucible OD 150 mm, H 150 mm |

| 33 | Al-ReC-027-007-006-00007 | Alumina Rectangle crucible 027 mm x 007 mm x 006 mm |

| 34 | Al-ReC-030-010-010-00008 | Alumina Rectangle crucible 030 mm x 010 mm x 010 mm |

| 35 | Al-ReC-050-020-020-00002 | 99% Alumina Rectangle crucible 50 mm x 20 mm x 20 mm |

| 36 | Al-ReC-050-020-010-00003 | 99.8% Alumina Rectangle crucible 50 mm x 20 mm x 10 mm |

| 37 | Al-ReC-075-018-014-00005 | 99.8% Alumina Rectangle crucible 75 mm x 18 mm x 14 mm |

| 38 | Al-ReC-075-019-010-00001 | 99% Alumina Rectangle crucible 75 mm x 19 mm x 10 mm |

| 39 | Al-ReC-090-065-030-00013-L | 99% Alumina Rectangle crucible 90mm x 65mm x 30mm Thickness 3-4mm with step lid 90mm x 65mm x 4mm |

| 40 | Al-ReC-100-040-0020-00017-L | 99.8% Alumina Rectangle crucible with lid 100 mm x 40 mm x 20 mm (50-1000ml) |

| 41 | Al-ReC-100-100-035-00006 | 99.8% Alumina Rectangle crucible 100 mm x 100 mm x 35 mm |

| 42 | Al-ReC-115-090-0030-00015 | 99.8% Alumina Rectangle crucible 115 mm x 90 mm x 30 mm (250ml) |

| 43 | Al-ReC-120-080-040-00014 | 99.8% Alumina Rectangle crucible 120 mm x 80 mm x 40 mm |

| 44 | Al-Rec-120-120-030-00010 | Alumina Rectangle Crucible 120 mm x 120 mm x 30 mm |

| 45 | Al-ReC-150-150-030-00009 | Alumina Rectangle crucible 150 mm x 150 mm x 030 mm |

| 46 | Al-ReC-150-150-0070-00016 | 99.8% Alumina Rectangle crucible 150 mm x 150 mm x 70 mm (1250ml) |

| 47 | Al-ReC-160-120-070-00011-H | Alumina Rectangle crucible with holes 160 mm x 120 mm x 070 mm |

| 48 | Al-ReC-160-120-070-00012 | Alumina Rectangle crucible 160 mm x 120 mm x 070 mm |

| 49 | Al-ReC-240-040-020-00004-L | 99.7% Alumina Rectangle crucible+Lid 240 mm x 40 mm x 20 mm |

| 50 | Al-BoC-113-30-20-00005 | 99.8% Alumina boat crucibles 113mm top length 30mm top width 18-20mm Height |

| 51 | Al-BoC-025-050-010-00002 | 99% Alumina Boat Crucible 25 mm x 50 mm x 10 mm |

| 52 | Al-BoC-028-056-014-00001 | 99% Alumina Boat Crucible 28 mm x 56 mm x 14 mm |

| 53 | Al-BoC-100-020-020-00004 | 95% Alumina Boat Crucible with 3 partition Length 100mm Width 20mm Height 20mm |

| 54 | Al-BoC-100-040-020-00003 | Alumina Boat Crucible 100 mm x 40 mm x 20 mm |

| 55 | Al-Dsk-005-0.5-0001 | Alumina Disk Dia 5mm x Th 0.5mm |

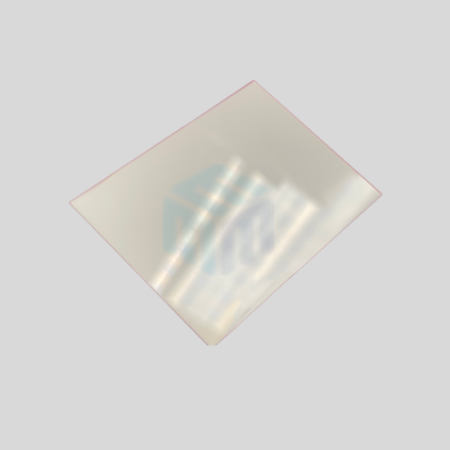

| 56 | Al-Plt-100-030-003-001 | Alumina Plate 100mm x 30mm x 3mm |

| 57 | Al-Plt-100-100-008-002 | Alumina Plate 100mm x 100mm x 8mm (Tolerance +/-0.01mm) |

| 58 | Customized Ceramic Crucibles: Alumina Boats, Alumina Trays, Alumina Cylindrical crucibles, Alumina Conical Crucibles, Alumina Rectangle Crucibles and other customize shapes | Please contact us for your customized requirements on +1-732-808-1999 or email info@mkubeenterprise.com |

Key Properties of Our Alumina Ceramic Crucibles

Our high-performance ceramic crucibles are designed to withstand the most demanding conditions:

- Heat resistance up to 1700°C

- Inert to acids, alkalis, and molten materials

- Excellent thermal shock resistance

- High mechanical strength and dimensional stability

- Non-contaminating and corrosion-resistant

- Ideal for high-purity analytical and thermal applications

These properties make our high-temperature crucibles a reliable choice for laboratories and industrial settings alike.

Applications of Alumina Ceramic Crucibles in Scientific and Industrial Fields

Our alumina crucibles are used across a variety of American industries, including:

- Analytical labs for ashing, melting, and calcination

- Thermal analysis such as TGA and DTA

- Sample prep in mining, metallurgy, and materials science

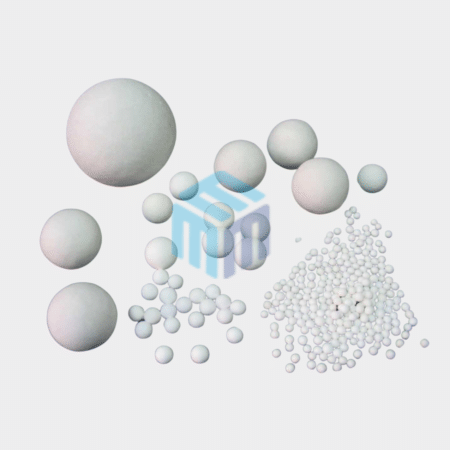

- Ceramic and metal powder processing

- Furnace studies in research institutions

- Environmental and geochemical testing

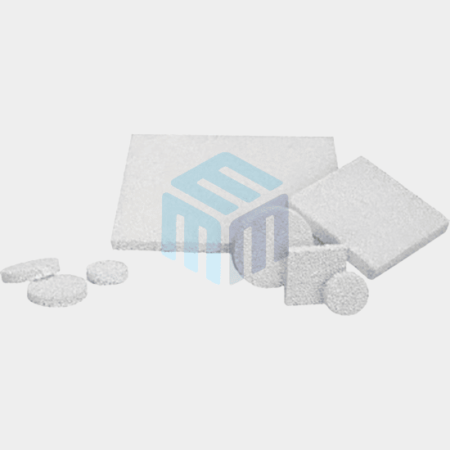

We also offer complementary products such as alumina tubes and rods, alumina plates, and alumina grinding media to support full laboratory setups.

Why Choose M-Kube for Alumina Crucibles in the USA?

M-Kube Enterprise is a trusted global supplier of alumina ceramics, delivering value, technical support, and performance to American labs and manufacturers:

- Fast delivery across the USA

- Stocked and custom ceramic solutions

- Reliable supply chain and technical advice

- Competitive pricing with volume discounts

- Support for USA compliance and quality standards

Our expertise in technical ceramics ensures that every alumina crucible you receive meets stringent specifications.

Reliable USA Supplier of High-Purity Alumina Crucibles

At M-Kube Enterprise, we provide high-purity alumina ceramic crucibles engineered for precision, thermal stability, and chemical resistance. Whether you’re working in a lab, furnace system, or production facility, we offer both standard sizes and custom solutions to meet your exact needs.

- Trusted by USA research labs, universities, and manufacturers

- Tight tolerances and high-performance ceramic quality

- Fast delivery and responsive customer support

📞 Call +1-732-808-1999 or

📧 Email us at info@mkubeenterprise.com

to request a quote or get expert guidance on your alumina crucible requirements.

Product FAQ's

Alumina crucibles are prized for high-temperature work in metallurgy, ceramics, chemical processing, and materials testing. Their purity and strength let you melt, calcine, or sinter samples without contamination, making them a staple in both lab and industrial furnaces.

Depending on purity and wall thickness, alumina crucibles can safely handle up to 1700 °C (3092 °F). High-grade ceramic versions resist thermal shock and chemical attack, ideal for demanding refractory applications.

Fine aluminum oxide powder (Al₂O₃) is shaped—cylindrical, boat-style, rectangular tray style or other—and then sintered at very high temperatures to produce a dense, durable ceramic vessel.

Alumina Crucibles are available in a purity range from 85% to 99.8% alumina. Typically grades of ≥99.5% are recommended for analytical or semiconductor work to minimize contamination and boost chemical resistance.

Gently remove loose debris by tapping or brushing.

Heat in a furnace or kiln to burn off organic residue.

Use non-abrasive ultrasonic baths or soft brushes for cleaning.

Avoid strong acids or harsh abrasives that can erode the ceramic.

Routine, gentle maintenance preserves integrity and ensures consistent results.

Alumina crucibles are available in various shapes to suit different applications, including cylindrical, conical, rectangular, boat-shaped and customised designs. These shapes are chosen based on the specific heating and material handling needs of laboratories or industrial setups.

Trusted alumina ceramic tube suppliers in the USA, such as M-Kube Enterprise, also offer custom alumina crucible shapes and sizes to meet unique requirements. With their expertise in high-temperature ceramic solutions, M-Kube Enterprise provides high-purity alumina crucibles tailored for durability and precision in demanding environments.