Alumina Customization Applications

Inquiry NowProduct Description

High purity alumina (HPA), also known as high-grade aluminum oxide, is a versatile material with a wide range of applications due to its exceptional properties, including high temperature resistance, excellent electrical insulation, and chemical inertness. Customization in HPA applications is often necessary to meet specific requirements for various industries. Here are some common applications and ways in which HPA can be customized:

- LED Substrates: Customized HPA substrates are used in LED manufacturing, particularly for high-power LEDs. The customization can involve precise dimensions, surface finishes, and purity levels to ensure uniform light emission and improved performance.

- Semiconductor Manufacturing: HPA wafers and substrates can be customized for semiconductor applications, including wafer size, thickness, surface quality, and orientation, to match the requirements of different semiconductor devices.

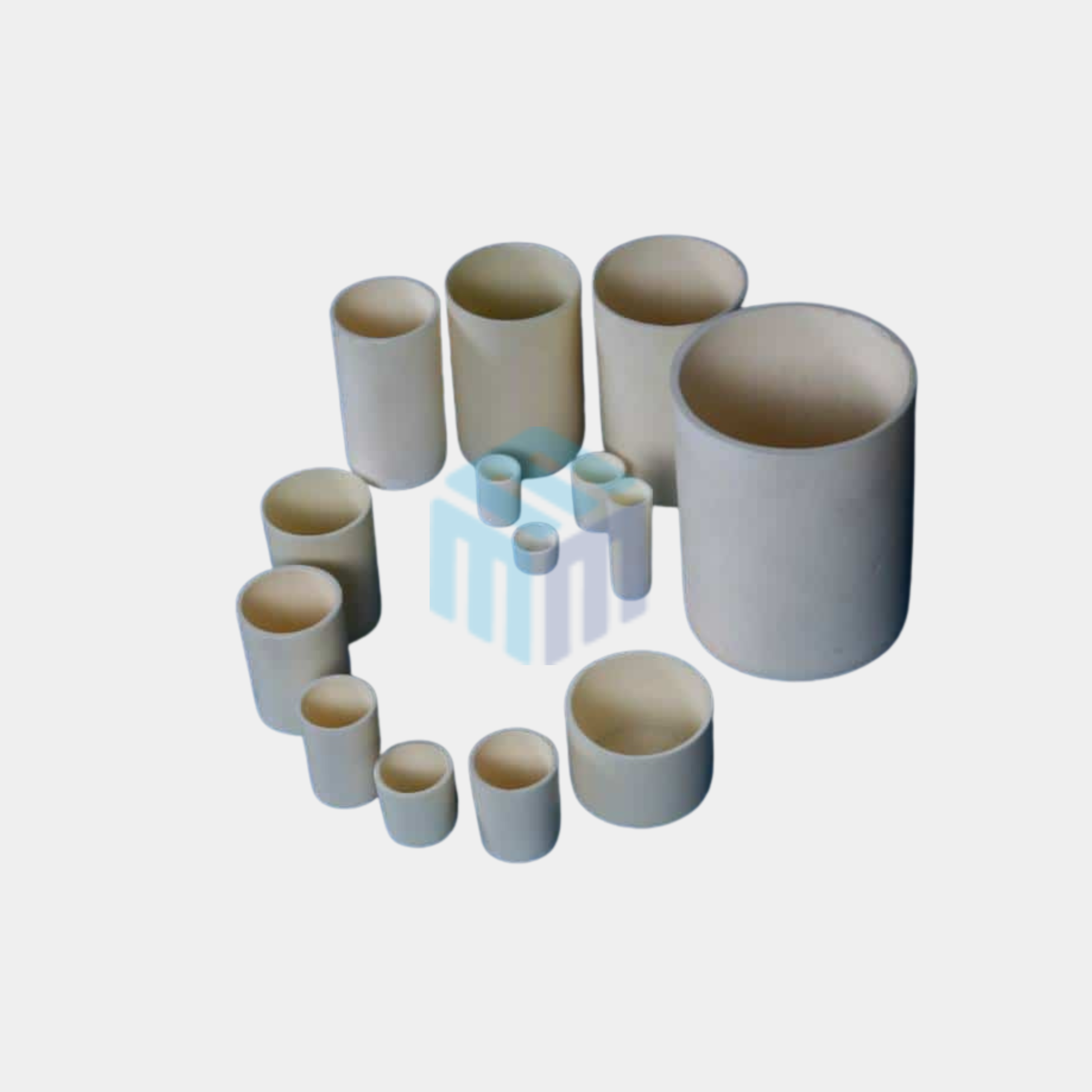

- High-Temperature Furnace Components: Customized HPA components, such as tubes, crucibles, and trays, are used in high-temperature furnace applications. They can be tailored for specific shapes, dimensions, and purity levels to withstand extreme thermal conditions.

- Electrical Insulators: HPA is an excellent electrical insulator. Customized HPA insulators can be designed to meet specific electrical, thermal, and mechanical requirements for applications in the electronics and electrical industries.

- Medical and Dental Ceramics: Customized HPA components can be used in medical and dental devices, such as dental implants, prosthetics, and surgical instruments. The customization can involve precise shaping, biocompatible coatings, and sterilization compatibility.

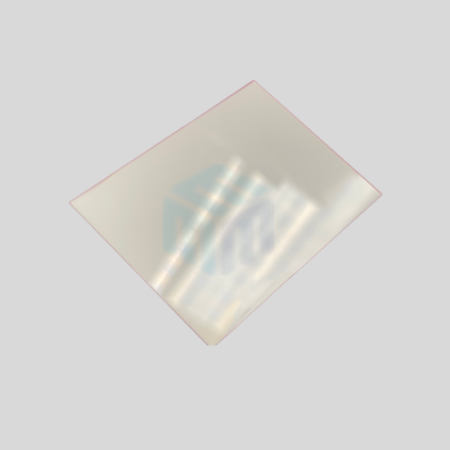

- Sapphire Substrates: HPA is used in the production of sapphire substrates for applications like watch crystals, optical windows, and smartphone camera lenses. Customization can involve precise dimension control and surface quality.

- Laser Windows: Customized HPA windows are used in high-power laser systems. They can be tailored for specific wavelengths, thicknesses, and coatings to ensure laser transmission and minimize heat-induced damage.

- Medical Diagnostics: Customized HPA components can be used in medical diagnostic devices, including microfluidic chips, where precise microstructure fabrication and biocompatibility are essential.

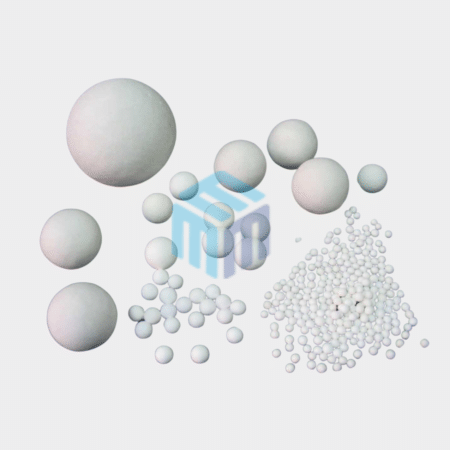

- Alumina Ceramic Bearings and Bushings: Customized HPA bearings and bushings can be tailored for specific applications, including extreme temperatures, high wear resistance, and lubrication-free operation.

- Sensors and Analytical Instruments: Customized HPA parts are used in various sensors and analytical instruments, where they can be designed to meet specific requirements for thermal stability, chemical resistance, and dimensional accuracy.

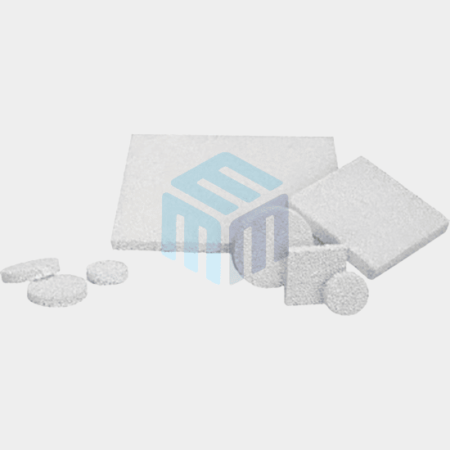

- Abrasives and Cutting Tools: HPA can be used in abrasive and cutting tool applications, and customization may involve designing ceramic tool inserts with specific shapes, sizes, and cutting characteristics.

To achieve customization in HPA applications, it is important to work with manufacturers or suppliers specializing in precision alumina ceramic fabrication. They can assist in the design, engineering, and production of HPA components to meet specific material properties, geometrical dimensions, surface finishes, and functional requirements, ensuring that the final product aligns with the intended application. Customization is crucial to optimize the performance and functionality of HPA in various industrial and technological sectors.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.