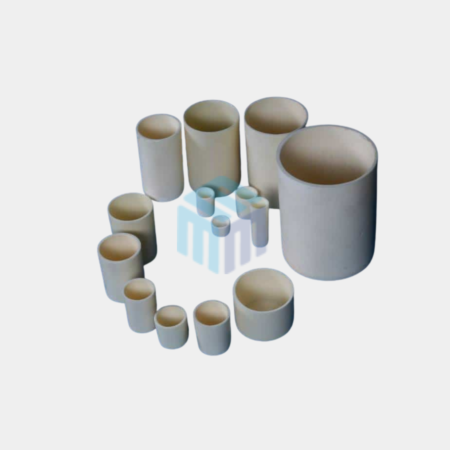

Alumina Tubes and Rods

Inquiry NowProduct Description

High-Purity Alumina Tubes and Rods – Engineered Ceramic Components for Industries

M-Kube Enterprise delivers premium alumina tubes and alumina rods made from high-purity aluminum oxide (Al₂O₃), designed to withstand extreme conditions. These advanced ceramic components offer superior thermal stability, electrical insulation, and chemical resistance—making them a top choice for high-temperature applications and wear-intensive environments.

Whether you’re in a laboratory, manufacturing facility, or research center in the USA, M-Kube provides both standard and custom alumina ceramic solutions tailored to your needs.

Standard & Custom Alumina Tubes and Rods – Precision You Can Count On

At M-Kube Enterprise, we understand the demands of precision engineering. That’s why we offer an extensive inventory of alumina rods and tubes in standard dimensions, along with custom-machined ceramic parts that meet tight tolerances (as precise as ±0.05mm, depending on customer requirements).

You can select from a variety of configurations including:

- Open- or closed-end tubes

- Multi-bore and multi-channel designs

- Dome ends, flanges, caps, and surface finishes

- Laser engraving, polishing, and labeling

- Rapid prototyping and scalable production

These components are ideal for replacing worn parts or developing prototypes in high-performance applications.

| Al-TbO-001-000.5-0100-00053 | 99.8% Alumina Tube, Both Ends open, OD 0.8-1 mm x ID 0.3-0.6 mm x L 100 mm |

| Al-TbO-002-001-0100-00008 | Alumina Tube, Both Ends open, OD 2 mm , ID 1 mm , Length 100 mm |

| Al-TbO-002-001-1000-00046 | 99.8% Alumina Tube, Both Ends open, OD 2mm x ID 1 mm x L 1000 mm |

| Al-TbO-002.8-001.8-0300-00054 | 99.8% Alumina Tube, Both Ends open, OD 2.7-3 mm x ID 1.7-2 mm x L 300 mm |

| Al-TbO-004-001.5-0500-00047 | 99.8% Alumina Tube, Both Ends open, OD 4mm x ID 1.5 mm x L 500 mm |

| Al-TbO-004-002-0100-00051 | 99.8% Alumina Tube, Both Ends open, OD 4mm x ID 2 mm x L 100 mm |

| Al-TbO-004-2bore-0100-00052 | 99.8% Alumina Tube, Both Ends open, OD 4mm with 2 bores x L 100 mm |

| Al-Rd-005-000-0200-00013 | 99.7% Alumina Rod, OD 5 mm, Length 200 mm |

| Al-Rd-005-000-0200-00013 | 99.7% Alumina Rod, OD 5 mm, Length 200 mm |

| Al-TbO-06.35-004-0300-00044 | 99.8% Alumina Tube, Both Ends open, OD 6.35 mm x ID 4 mm x L 300 mm |

| Al-TbO-007.9-004.8-0500-00047 | 99.8% Alumina Tube, Both Ends open, OD 7.9mm x ID 4.8 mm x L 500 mm |

| Al-TbO-008.5-007-0080-0021 | 99.7% Alumina Tube, Both Ends open, OD 8.5 mm, ID 07 mm, Length 80 mm |

| Al-TbC-009-003-0200-00009 | Alumina Tube, One Ends open, OD 9 mm , ID 3 mm , Length 200 mm |

| Al-TbO-010-007-0100-00005 | Alumina Tube, Both Ends open, OD 10 mm , ID 7 mm , Length 100 mm |

| Al-TbO-013.5-010.8-0022-00050 | 99.8% Alumina Tube, Both Ends open, OD 13.5mm (tolerance +0.4mm) x ID 10.8mm (tolerance +0.4mm) x L 22 mm |

| Al-TbO-015-010-0200-00012 | 99.7% Alumina Tube, Both Ends open, OD 15 mm , ID 10 mm , Length 200 mm |

| Al-TbO-017.5-015-0050-0020 | 99.7% Alumina Tube, Both Ends open, OD 17.5 mm, ID 15 mm, Length 50 mm |

| Al-TbO-025-013-0500-00004 | 76% Alumina Tube, Both Ends open, OD 25 mm , ID 13 mm, Length 500 mm |

| Al-TbO-020-015-0300-00014 | 99.7% Alumina Tube, Both Ends open, OD 20 mm, ID 15 mm, Length 300 mm |

| Al-TbO-020-015-0325-00017 | 99.7% Alumina Tube, Both Ends open, OD 20 mm, ID 15 mm, Length 325 mm |

| Al-TbO-020-015-0500-00033 | 99.7% Alumina Tube, Both Ends open, OD 20 mm , ID 15 mm , Length 500 mm |

| Al-TbO-030.5-026.5-0100-00030 | 99.7% Alumina Tube, Both Ends open, OD 30.5 mm x ID 26.5 mm x L 100 mm |

| Al-TbO-030.5-026.5-0500-00029 | 99.7% Alumina Tube, Both Ends open, OD 30.5 mm x ID 26.5 mm x L 500 mm |

| Al-TbO-040-030-0100-00039 | 99.7% Alumina Tube, Both Ends open, OD 40 mm , ID 30 mm , Length 100 mm |

| Al-TbO-040-030-0250-00019 | 99.7% Alumina Tube, Both Ends open, OD 40 mm, ID 30 mm, Length 250 mm |

| Al-TbO-040-030-0255-00034 | 99.7% Alumina Tube, Both Ends open, OD 40 mm , ID 30 mm , Length 255 mm |

| Al-TbO-040-34-0500-00048 | 99.7% Alumina Tube, Both Ends open, OD 40mm x ID 34mm x L 500 mm, Tolerance +-0.5 to 1mm |

| Al-TbO-040-032-1000-00035 | 99.7% Alumina Tube, Both Ends open, OD 40 mm , ID 32 mm , Length 1000 mm |

| Al-TbO-040-020-1120-00003 | 76% Alumina Tube, Both Ends open, OD 40 mm , ID 20 mm , Length 1120mm |

| Al-TbO-045-041-0255-00037 | 99.7% Alumina Tube, Both Ends open, OD 45 mm , ID 41 mm , Length 255 mm |

| Al-TbO-050-040-0100-00011 | 99.7% Alumina Tube, Both Ends open, OD 50 mm , ID 40 mm , Length 100 mm |

| Al-TbO-050-040-0100-00016 | 99.7% Alumina Tube, Both Ends open, OD 50 mm , ID 40 mm , Length 200 mm |

| Al-TbO-050-040-1000-00002 | 99.7% Alumina Tube, Both Ends open, OD 50 mm , ID 40 mm , Length 1000 mm |

| Al-TbO-050-040-1000-00006 | 99.8% Alumina Tube, Both Ends open, OD 50 mm , ID 40 mm , Length 1000 mm |

| Al-TbO-058-050-0535-00036 | 99.7% Alumina Tube, Both Ends open, OD 58 mm , ID 50 mm , Length 535 mm |

| Al-TbO-060-050-1000-00001 | 99.7% Alumina Tube, Both Ends open, OD 60 mm , ID 50 mm , Length 1000 mm |

| Al-TbO-060-050-1400-00032 | 99.7% Alumina Tube, Both Ends open, OD 60 mm x ID 50 mm x L 1400 mm |

| Al-TbO-063-053-0568-00018 | 99.7% Alumina Tube, Both Ends open, OD 63 mm, ID 53 mm, Length 568 mm |

| Al-TbO-065-058-0568-00015 | 99.7% Alumina Tube, Both Ends open, Wall thickness 3mm, Grind 100 mm both End and make OD 63 at the end. OD 65 mm, ID 58 mm, Length 568 mm |

| Al-TbO-070-060-0600-00042 | 99.7% Alumina Tube, Both Ends open, OD 70 mm x ID 60 mm x L 600 mm |

| Al-TbO-070-060-0500-00031 | 99.7% Alumina Tube, Both Ends open, OD 70 mm x ID 60 mm x L 500 mm |

| Al-TbO-080-060-0150-00043 | 99.7% Alumina Tube, Both Ends open, OD 80 mm x ID 60 mm x L 150 mm |

| Al-TbO-080-070-1000-00022 | 99.7% Alumina Tube, Both Ends open, OD 80 mm, ID 70 mm, Length 1000 mm |

| Al-TbO-090-080-0060-00007 | 99.7% Alumina Tube, Both Ends open, OD 90 mm , ID 80 mm , Length 60 mm |

| Al-TbO-090-080-0060-00007-H | 99.7% Alumina Tube, Both Ends open, w HOLE OD 90 mm , ID 80 mm , Length 60 mm |

| Al-TbO-090-80-0500-00049 | 99.7% Alumina Tube, Both Ends open, OD 90mm x ID 80mm x L 500 mm, Tolerance +-1.5mm |

| Al-TbO-090-080-650-00041 | 99.7% Alumina Tube, Both Ends open, OD 90 mm , ID 80 mm , Length 650 mm |

| Al-TbO-095-085-1000-00038 | 99.7% Alumina Tube, Both Ends open, OD 95 mm , ID 85 mm , Length 1000 mm |

| Al-TbO-100-090-150-00040 | 99.7% Alumina Tube, Both Ends open, OD 100 mm(+/-0.5) , ID 90 mm , Length 1500 mm |

| Custom sizes can be made available upon request.

Call us at +1-732-808-1999or email us info@mkubeenterprise.com for more information. |

Key Features of Our Alumina Tubes and Rods

M-Kube Enterprise’s ceramic products are made to perform. Key material properties include:

- High-temperature resistance up to 1700°C

- Exceptional electrical insulation for electronic and power systems

- Corrosion resistance to acids, alkalis, and gases

- Wear and abrasion resistance

- Low thermal expansion for dimensional stability

- Biocompatibility for medical and lab use

These features make our alumina tubes and rods essential for precision-critical environments.

Applications of Alumina Tubes and Rods for Industrial and Scientific Sectors

Our alumina tubes and rods are trusted across diverse USA industries:

- Furnace and kiln thermocouple protection tubes

- Vacuum systems and plasma chambers

- High-voltage electrical insulators

- Reaction vessels and lab sample holders

- Flow guides and abrasion-resistant linings

For high-temperature testing, don’t forget to explore our alumina crucibles and high precision alumina plates.

Why Choose M-Kube for Alumina Ceramic Solutions in the USA?

M-Kube Enterprise is a dependable partner for high-purity ceramic components across the United States. Here’s what sets us apart:

- USA-friendly supply and logistics support

- Fast quotes and responsive customer service

- Custom-engineered ceramic parts

- Competitive pricing for both small and bulk orders

- Trusted by universities, labs, and industrial facilities

Our global partnerships ensure that every alumina tube and alumina rod meets international performance standards.

Your Trusted USA Supplier for Alumina Tubes and Rods

M-Kube Enterprise specializes in precision-engineered ceramic components designed for extreme temperatures and demanding technical environments. Whether you need standard sizes or custom-machined parts, we’re here to support your requirements with quality, speed, and expertise.

- Consistent dimensional accuracy

- Customization support for research and industrial use

- Fast, reliable service across the USA

📞 Call +1-732-808-1999 or

📧 Email us at info@mkubeenterprise.com

to request a quote or speak with a materials expert today.

Product FAQ's

Alumina tubes can typically withstand temperatures up to 1700°C/1800°C (3092°F), depending on the purity of the material and the wall thickness. These high-performance tubes are suitable for use in both oxidizing and reducing environments, making them a dependable option for a range of industrial and laboratory applications. Their durability and stability under extreme heat conditions ensure consistent performance in high-temperature processes.

Alumina tubes and rods are widely used in industries that demand high thermal resistance, chemical durability, and excellent electrical insulation. Common applications include:

Semiconductor processing

-Analytical instrumentation

-High-temperature furnaces

-Aerospace

-Chemical processing

-Research and development laboratories

Products like alumina furnace tubes and alumina rods are especially valued in these environments due to their ability to perform reliably under extreme conditions. Trusted alumina tube suppliers in the USA typically serve these industries with high-purity, precision-engineered components tailored to specific application needs.

Alumina tubes are generally manufactured with a purity level between 95% and 99.8%. This high-purity alumina provides excellent mechanical strength, thermal stability, and chemical resistance, making it suitable for use in demanding environments.

Many alumina ceramic tube suppliers in the USA offer these high-purity tubes for applications in industries such as electronics, aerospace, and high-temperature furnace operations. Whether you’re sourcing alumina tubes or looking for components for precision industrial use, this level of purity ensures reliable performance under extreme conditions.

Alumina tubes are designed to tolerate continuous operating temperatures ranging from 1600°C to 1700°C, depending on factors such as the tube’s configuration and the surrounding environment. These high-performance components are engineered to resist deformation and wear under extreme heat, making them ideal for industrial furnaces, thermal processing, and other demanding applications. They are widely used in industries where thermal stability and reliability are critical.

Yes, alumina tubes are highly resistant to chemical corrosion, making them ideal for use in both acidic and basic environments. This durability makes them a preferred choice in industries like chemical processing, where traditional metal tubes may fail over time. Both alumina rods and tubes are valued for their long-term performance under harsh conditions.

Yes, custom sizes are commonly available for alumina tubes to meet specific application requirements. Many alumina tube suppliers in the USA offer custom fabrication services, allowing for tailored diameters, lengths, tight tolerances, custom machining and varied configurations.

Whether it’s for alumina furnace tubes used in high-temperature systems or precision alumina rods for lab and industrial use, reliable alumina ceramic tube suppliers can deliver solutions designed to fit unique performance needs.

Ans: If you’re looking for reliable alumina furnace tube suppliers in the USA, M-Kube Enterprise is a trusted provider specializing in high-purity ceramic components designed for demanding industrial environments. Serving industries such as aerospace, chemical processing, and high-temperature manufacturing, M-Kube offers both standard and custom alumina ceramic tube solutions.

Their products are engineered to perform reliably in extreme heat and corrosive environments, with technical support available to help ensure the right fit for your specific application. Whether you need precision tolerances or high-purity material, M-Kube Enterprise delivers quality and performance in every product.

Choosing the right alumina furnace tube depends on key factors such as operating temperature, chemical exposure, and mechanical stress. Additionally, the material’s purity and wall thickness play a vital role in its durability and efficiency. It’s best to consult with a knowledgeable alumina furnace tube supplier who can help match the product to your specific application requirements.