Boron Nitride Crucible

Inquiry NowProduct Description

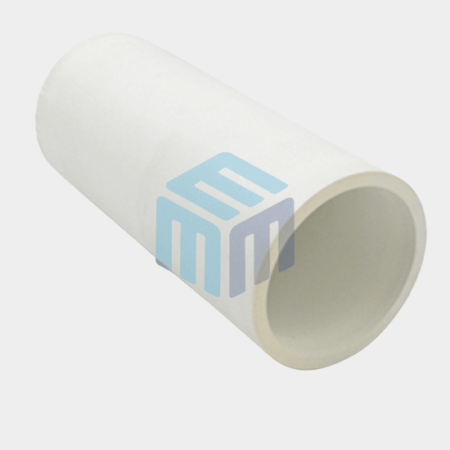

Boron Nitride Crucibles – High-Purity BN Ceramic Crucibles for Extreme Conditions

M-Kube Enterprise supplies high-performance boron nitride crucibles made from hexagonal boron nitride (h-BN), a unique ceramic known for its exceptional thermal conductivity, electrical insulation, and non-reactivity with molten metals. These crucibles are widely used in vacuum systems, metal processing, and crystal growth across demanding sectors like aerospace, semiconductors, and advanced materials research in the USA

With a structure similar to graphite, BN crucibles are engineered to perform in environments where chemical purity and thermal stability are critical.

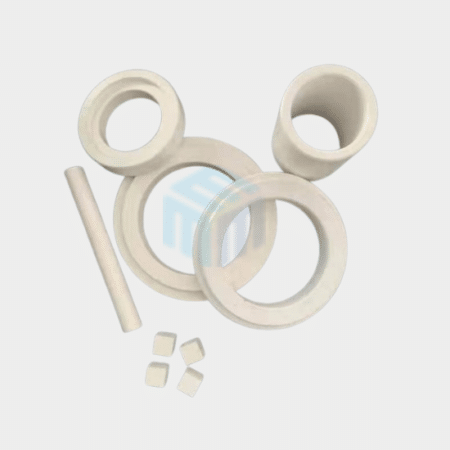

Standard and Custom BN Crucibles for Industrial and Research Applications

We offer both standard BN crucibles and custom-machined boron nitride solutions for your precise thermal and chemical needs. From prototype samples to full production, M-Kube Enterprise delivers consistent quality and application-specific performance.

Customization capabilities include:

- Cylindrical, conical, tapered, or square shapes

- Custom thicknesses and volumes

- Polished, porous, or textured finishes

- Machined forms compatible with vacuum or inert systems

- Tight-tolerance parts for sensitive processes

Our boron nitride ceramic crucibles are available for use in reducing atmospheres, PVD systems, and high-purity molten metal operations.

Key Properties of BN Crucibles

Boron nitride crucibles are uniquely suited to advanced applications due to their:

- Extremely high melting point (~2973°C)

- High thermal shock resistance

- Non-wettability to molten aluminum, magnesium, and zinc

- Strong electrical resistivity even at elevated temperatures

- Chemically inert surfaces, ideal for reactive environments

- Self-lubricating, low-friction ceramic structure

These benefits make BN crucibles a go-to choice for molten metal casting, vacuum evaporation, and electronic material processing.

Applications of Boron Nitride Crucibles in Industries

BN crucibles are used extensively across high-tech USA industries, including:

- Molten metal containment for aluminum and magnesium alloys

- Vacuum evaporation and PVD deposition systems

- Crystal growth and optical material processing

- Semiconductor and thin-film R&D

- Thermal analysis and dielectric studies

- Furnace components and sample prep in analytical labs

Also explore our magnesia crucibles, alumina crucibles, and other ceramic products for your high-temperature applications.

Why Engineers and Scientists Choose M-Kube Enterprise for BN Crucibles?

M-Kube Enterprise is a trusted supplier of boron nitride ceramics, offering expert support and custom solutions to meet your unique application needs:

- High-purity machinable BN ceramics

- Reliable supply chain and short lead times

- Support for both R&D and large-scale production

- U.S.-friendly service with technical guidance

- Commitment to international performance standards

We help ensure your high-precision thermal processes run cleanly, consistently, and contamination-free.

USA Based Supplier of High-Purity Boron Nitride Crucibles

M-Kube Enterprise offers premium-grade hexagonal boron nitride (h-BN) crucibles with excellent thermal conductivity, electrical insulation, and non-wettability to molten metals. Ideal for crystal growth, metal casting, vacuum evaporation, and semiconductor R&D, our BN crucibles are engineered to perform under extreme conditions.

- Non-reactive to aluminum, magnesium, and zinc melts

- Custom geometries and surface finishes available

- Stable in vacuum, inert, and reducing atmospheres

📞 Call +1-732-808-1999 or

📧 Email us at info@mkubeenterprise.com

to request a quote or discuss your boron nitride crucible application with our technical team.

Product FAQ's

A boron nitride (BN) crucible is a high-performance ceramic vessel made from hexagonal boron nitride. It is valued for its excellent thermal stability, chemical inertness, and non-wetting surface, making it ideal for maintaining material purity under high-temperature conditions. These crucibles are commonly used in demanding laboratory and industrial applications.

Yes. Boron nitride crucibles resist wetting by metals such as aluminum, magnesium, zinc, and even precious metals. Their non-adhesive surface makes metal removal straightforward and prevents corrosion or erosion, which is why BN crucibles are often specified for metal casting applications.

BN crucibles come in a range of standard and custom dimensions—from small R&D boats up to large production-scale cylinders. Boron nitride crucibles are typically offered in diameters from a few millimeters to several inches, with heights to suit most furnace designs, by BN suppliers in the USA, such as M-Kube Enterprise.

Common uses include:

-Metal casting and alloy melting

-Crystal growth (e.g., GaN, AlN)

-Vacuum or inert-atmosphere furnace processes

-Semiconductor manufacturing

-Non-oxide material synthesis

Their combination of electrical insulation and thermal shock resistance also makes them popular in aerospace and advanced materials research

Under vacuum or inert conditions, BN crucibles perform up to about 1800 °C (3272 °F). In air, they begin to oxidize above roughly 850 °C, so applications above this temperature typically use inert atmospheres or dedicated boron nitride crucible designs.

Yes. You can choose from fully dense BN crucibles for maximum mechanical strength or composite versions (e.g., BN reinforced with SiC) to boost thermal conductivity and toughness, depending on your application needs.

Gently brush or wipe away loose residues

-Use mild solvents (like isopropyl alcohol) for light cleaning

-Avoid strong acids and abrasive tools that can damage the BN surface-

-For stubborn deposits, perform a low-temperature bakeout in an inert atmosphere

Routine, gentle cleaning preserves the non-wetting properties and extends the life of your crucible.