Magnesia Customization Applications

Inquiry NowProduct Description

Magnesia, or magnesium oxide (MgO), is a versatile material with a wide range of applications in various industries. Customization in magnesia applications is essential to meet specific requirements for different use cases. Here are some common applications and ways in which magnesia can be customized:

- Refractories: Magnesia-based refractory materials are used in high-temperature applications such as steelmaking, cement production, and glass manufacturing. Customization may involve the design of refractory shapes, compositions, and thermal properties to withstand specific operating conditions.

- Magnesium Oxide Boards: Customized MgO boards are used in construction and fireproofing applications. The customization can include board thickness, dimensions, surface finishes, and fire resistance ratings to meet building specifications.

- Agriculture: Magnesia is used as a soil conditioner and a source of magnesium in agriculture. Customization may involve the formulation of specific magnesia-based fertilizers tailored to soil and crop needs.

- Pharmaceuticals: Magnesia is used in pharmaceuticals as an antacid and laxative. Customization can involve the formulation of specific magnesium oxide compounds with precise purity levels and particle sizes for pharmaceutical use.

- Ceramics: Customized magnesia materials are used in ceramics manufacturing. The customization may involve specific compositions and particle sizes to achieve desired ceramic properties, such as thermal expansion and strength.

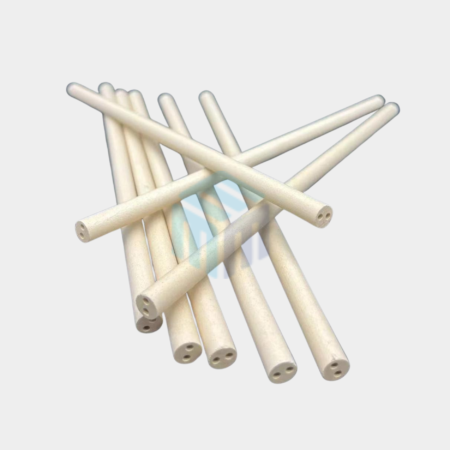

- Magnesium Oxide Insulation: Customized MgO insulation materials are used in high-temperature industrial applications and in the construction of thermal and electrical insulation systems. The customization can include insulation thickness, composition, and thermal conductivity properties.

- Magnesium Oxide Nanoparticles: Customized MgO nanoparticles are used in nanotechnology and advanced materials. The customization can involve specific particle sizes, surface modifications, and dispersion characteristics for various applications, such as catalysts and nanocomposites.

- Desulfurization: In the power generation industry, magnesia can be customized for flue gas desulfurization processes. Customization may involve the design of sorbents with specific reactivity and reusability properties for sulfur removal.

- Electrical Components: Customized magnesia materials can be used in electrical components like insulators and resistor substrates. Customization can involve specific electrical and thermal properties to meet the needs of electronic circuits.

- Food Additives: Magnesia is used as a food additive to adjust the pH of food products. Customization can include the formulation of food-grade magnesium oxide compounds with precise purity and particle sizes.

- Environmental Remediation: Magnesia can be customized for environmental remediation applications, such as treating acidic mine drainage or reducing heavy metal contamination in soil. Customization may involve the design of sorbents with specific adsorption and precipitation properties.

To achieve customization in magnesia applications, it is essential to work with manufacturers or suppliers specializing in magnesia production and processing. These experts can assist in the design, engineering, and production of magnesia-based materials to meet specific material properties, compositions, geometrical dimensions, and functional requirements, ensuring that the final product aligns with the intended application. Customization is crucial to optimize the performance and functionality of magnesia in various industrial and technological sectors.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.