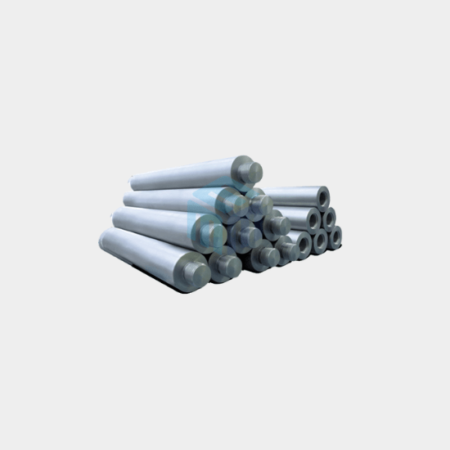

Molybdenum Rods

Inquiry NowProduct Description

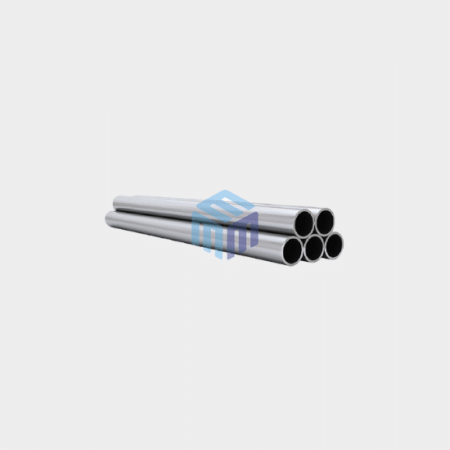

Molybdenum Rods, Tubes & Bars – High-Temperature Metal Components for Furnaces and Industrial Applications

M-Kube Enterprise supplies high-purity molybdenum rods, molybdenum tubes, and molybdenum bars engineered for extreme thermal, electrical, and mechanical environments. With a melting point above 2600°C and excellent structural stability, these components are widely used in vacuum furnaces, semiconductor equipment, aerospace systems, and material testing across the USA

These refractory metal components are ideal for applications demanding heat resistance, conductivity, and dimensional precision.

Custom Molybdenum Rods, Tubes & Bars Built for Demanding Applications

We offer both standard and custom molybdenum rod and tube solutions tailored to your exact operational requirements. Whether you need rods for furnace heating elements, glass sealing electrodes, or high-load support structures, M-Kube Enterprise delivers parts with tight tolerances and purity certifications.

Customization options include:

- Rod diameters from micro-scale to 120 mm

- Lengths cut to precise specifications

- Surface finishes: black, polished, or ground

- Pure molybdenum or alloyed grades (TZM, Mo-La)

- Swaged, forged, or sintered finishes

We support both prototype orders and high-volume production for USA-based labs and manufacturers.

Key Material Properties of Molybdenum Rods, Tubes & Bars

Molybdenum offers exceptional strength, conductivity, and high-temperature performance:

Technical Specifications

| Property | Specification |

|---|---|

| Material | Pure Molybdenum (≥99.95% Purity) |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Boiling Point | 4639°C |

| Thermal Conductivity | 138 W/m·K at 20°C |

| Electrical Conductivity | 1.87 × 10⁶ S/m |

| Tensile Strength | 400 – 900 MPa (Varies by Processing) |

| Elongation | 10 – 30% |

| Hardness (HV) | 200 – 250 HV |

| Oxidation Resistance | Requires Protective Atmosphere Above 400°C |

| Available Dimensions | ᵩ0.8 – ᵩ120mm x L (Customization requirements can be reviewed based on customer’s drawings/ request) |

| Surface Finish | Black, Polished, or Ground |

| Processing Methods | Sintering, Swaging, Forging, Machining |

Industrial Applications of Molybdenum Rods, Tubes & Bars

Molybdenum components are critical in high-stress environments across industries including:

- Heating elements and supports in vacuum/inert gas furnaces

- Electrodes and contact pins for glass-to-metal seals and electronics

- Radiation shielding and thermal plates for medical and defense

- Semiconductor manufacturing and thin-film deposition

- Tooling inserts and high-strength alloy components

- X-ray and high-energy physics equipment

Interested in alternatives? We also offer tantalum rods, titanium rods, and tungsten rods for other thermal and chemical applications.

Why USA Manufacturers Trust M-Kube Enterprise for Molybdenum Components

As a leading supplier, M-Kube Enterprise delivers both off-the-shelf and custom molybdenum rods, tubes, and bars to meet strict USA manufacturing standards:

- Certified high-purity materials

- Precise dimensional control

- Short lead times on stocked and custom parts

- Responsive engineering and sourcing support

- Global supply strength with localized service

Global-Standard Molybdenum Rods Backed by USA-Friendly Support

M-Kube Enterprise serves clients across the USA and globally, offering molybdenum metal solutions manufactured to international quality standards. From semiconductor fabs to aerospace labs, our customers trust us for performance-critical metal components delivered with expert support and fast turnaround.

Top USA Supplier of Molybdenum Rods, Tubes & Bars for Industrial and High-Temperature Applications

M-Kube Enterprise specializes in high-purity molybdenum rods, tubes, and bars engineered for use in aerospace, electronics, and high-temperature industrial processes. With a melting point over 2600°C, our molybdenum products offer exceptional thermal stability, mechanical strength, and corrosion resistance to meet your most demanding applications.

- Precision-manufactured rods, tubes, and bars in standard and custom sizes

- Ideal for high-temperature furnaces, electronic components, and chemical processing

- Expert technical support and fast shipping throughout the USA

📞 Call +1-732-808-1999 or

📧 Email us at info@mkubeenterprise.com

to request a quote or get expert advice for your molybdenum rods, tubes, and bars needs.

Product FAQ's

Molybdenum rods are made from high-purity molybdenum metal, a refractory metal known for its excellent strength, high melting point, and resistance to corrosion and thermal expansion. This makes molybdenum rods ideal for use in high-temperature industrial and scientific applications.

Standard molybdenum rods come as round bars with diameters from 0.5 mm to 120 mm and lengths up to 1000 mm or more. Many suppliers—including your preferred molybdenum rods supplier—also machine them into square or custom profiles on request.

Molybdenum rods serve wherever extreme heat and mechanical reliability are essential: aerospace, defense, semiconductor fabrication, glass and LED production, and high-temperature furnace components. Molybdenum rods suppliers often tailor grades to each sector’s specific needs.

In vacuum, molybdenum rods remain stable up to about 2900 °C, and in inert atmospheres up to 1900 °C. This ultra-high refractoriness makes them ideal for the most severe thermal environments.

Yes—molybdenum rods resist corrosion in non-oxidizing and acidic media at elevated temperatures. However, they oxidize rapidly above 600 °C in air, so a protective inert atmosphere or vacuum is recommended for hotter applications.

Absolutely. You can machine molybdenum rods using carbide tooling, and weld them under argon or another protective gas. Your molybdenum rods supplier can provide guidance on best practices to avoid oxidation and cracking during fabrication.