Quartz Crucibles

Inquiry NowProduct Description

Quartz Crucibles – Fused Silica Crucibles for High-Temperature and Chemical Purity

M-Kube Enterprise offers high-purity quartz crucibles made from premium fused silica—engineered to perform in high-temperature, chemically inert, and precision-sensitive environments. With superior thermal shock resistance and minimal expansion, these crucibles are ideal for applications in semiconductor processing, lab research, and metal refining across the USA

Whether you’re working with silicon wafers or conducting high-temperature analytical testing, M-Kube Enterprise provides quartz crucibles built for durability, purity, and performance.

Standard and Custom Quartz Crucibles for Laboratory and Industrial Use

We manufacture and supply both standard quartz crucibles and custom quartz crucibles to meet unique thermal and dimensional requirements. From semiconductor crystal growth to high-purity metal melting, M-Kube Enterprise ensures each crucible is tailored to your exact application.

Customization applications options include:

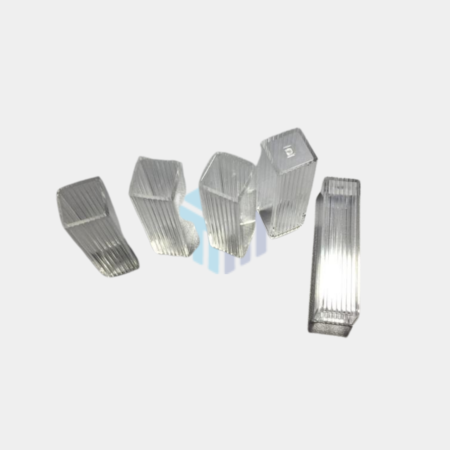

- Cylindrical, rectangular, conical, boat, and dish-shaped designs

- Natural or synthetic fused silica

- Ground, flame-finished, or polished surfaces

- Lids and accessories

- Wall thickness, depth, and diameter adjustments

Our quartz crucibles are manufactured to meet strict tolerances and can support both R&D and high-volume production in the USA

| S.No | Product Code | Description |

| 1 | Qu-BoC-030-010-005-00001-R | Quartz Boat Crucible with Ring 30 mm x 10 mm x 5 mm |

| 2 | Qu-BoC-050-010-005-00002-R | Quartz Boat Crucible with Ring 50 mm x 10 mm x 5 mm |

| 3 | Qu-BoC-050-020-010-00003-R | Quartz Boat Crucible with Ring 50 mm x 20 mm x 10 mm |

| 4 | Qu-BoC-050-025-012-00004-R | Quartz Boat Crucible with Ring 50 mm x 25 mm x 12 mm |

| 5 | Qu-BoC-050-030-015-00005-R | Quartz Boat Crucible with Ring 50 mm x 30 mm x 15 mm |

| 6 | Qu-BoC-100-015-007-00006-R | Quartz Boat Crucible with Ring 100 mm x 15 mm x 7 mm |

| 7 | Qu-BoC-100-025-012.5-00007-R | Quartz Boat Crucible with Ring 100 mm x 25 mm x 12.5 mm |

| 8 | Qu-BoC-100-050-025-00008-R | Quartz Boat Crucible with Ring 100 mm x 50 mm x 25 mm |

| 9 | Qu-C-025-000-038-00010-L | Quartz Crucible with Lid Dia 25 mm, H 38 mm, Tall Form, 30ml |

| 10 | Qu-C-048-000-015-00011-T | Basin Quartz Crucible OD 48 mm, H 15 mm, Thickness 2mm, Low Form |

| 11 | Qu-ReC-020-015-030-00002 | Quartz Rectangle Crucible 20 mm x 15 mm x 30 mm (thickness 2.5mm) |

| 12 | Qu-ReC-100-015-015-00001 | Quartz Rectangle Crucible 100 mm x 15 mm x 15 mm |

| 13 | Qu-CyC-025—–070-0004-L | Quartz clear cylindrical crucible 25-28 mm Diameter; 70-73 mm Tall; with lid |

| 14 | Qu-CyC-058-054-060-0003 | Quartz cylindrical crucibles OD 58mm ID 54mm H 60mm |

| 15 | Qu-CyC-060-056-0053-00001 | Quartz cylindrical crucibles OD 60mm ID 56mm H 53mm (2mm thickness) |

| 16 | Qu-CyC-060-056-0060-00002 | Quartz cylindrical crucibles OD 60mm ID 56mm H 60mm (2mm thickness) |

| CUSTOM SIZES of Quartz Boats, Quartz trays, Cylindrical Quartz crucibles, Conical Quartz crucibles, rectangle Quartz crucibles and many other customized designs can be made available upon request. |

Call us at +1-732-808-1999or email us at info@mkubeenterprise.com for more information. |

Key Properties of Quartz Crucibles – Thermal, Optical, and Chemical Excellence

Our fused quartz crucibles offer an exceptional combination of material characteristics:

- Melting point ~1700°C

- Operational use up to ~1180°C

- High resistance to thermal shock

- Low thermal expansion coefficient

- Chemical purity ≥99.99%

- Inert to most acids and bases (except hydrofluoric acid)

- Excellent optical and microwave transparency

These attributes make them ideal for contamination-sensitive, high-precision applications.

Industrial Applications of Fused Quartz Crucibles

M-Kube Enterprise’s quartz crucibles are widely used across American industries, including:

- Semiconductor wafer production (Czochralski method)

- Laboratory ashing, melting, and sample prep

- Glass melting and specialty glass fabrication

- Chemical and high-temperature analytical testing

- Metal alloy processing and crucible casting

Looking for alternatives for specific conditions? Check out our alumina crucibles or boron nitride crucibles for different thermal and chemical compatibility.

Why M-Kube Enterprise Is a Preferred Quartz Crucible Supplier in the USA?

As a trusted supplier of fused quartz crucibles, M-Kube Enterprise supports research labs, universities, foundries, and high-tech manufacturers across the USA

Here’s why customers choose us:

- Global-quality quartz with local service

- Broad range of stock and customizable application solutions

- Technical support from materials experts

- Reliable supply for both bulk and custom requirements

- Fast international shipping and responsive customer care

Your Trusted USA Supplier for Quartz Crucibles

M-Kube Enterprise provides top-grade fused silica quartz crucibles designed for high-temperature, chemical-resistant applications such as semiconductor processing, laboratory testing, and material synthesis. We offer a variety of standard shapes and custom sizes tailored to your operational needs.

- Excellent thermal shock resistance and purity (≥99.99%)

- Cylindrical, rectangular, and boat-shaped designs available

- Fast response and expert support across the USA

📞 Call +1-732-808-1999 or

📧 Email us at info@mkubeenterprise.com

to request a quote or discuss your quartz crucible specifications today.

Product FAQ's

A quartz crucible is a vessel made from high-purity fused quartz, designed to handle extremely high temperatures without contaminating materials. They are commonly used in semiconductor manufacturing, laboratory research, and metal or glass processing. These crucibles are available in various shapes, such as straight-walled cylinders and boat-style designs, to suit different furnace configurations.

Fused quartz crucibles can operate continuously between 1100 °C and 1200 °C (2012 °F–2192 °F). Their superior thermal stability allows them to retain shape and purity even under sustained high heat.

-Rinse with deionized water to remove loose particles

-Soak briefly in a mild acid solution (e.g., dilute HCl) for stubborn residues

-Never use hydrofluoric acid, as it corrodes quartz

-Rinse again and dry with lint-free cloths or air-dry in a clean area

Routine, gentle cleaning helps maintain both the crucible’s integrity and experimental accuracy.

Fused quartz has a low coefficient of thermal expansion, so it resists cracking during temperature changes. However, minimizing abrupt thermal shocks will extend the life of your crucible.

Absolutely. Most quartz crucible suppliers in the USA provide custom fabrication—letting you specify diameter, height, wall thickness, and even special end shapes to fit your furnace or lab equipment. You can also share your custom designs and drawings, which can be manufactured.

-Cylindrical crucibles in various diameters and heights

-Boat-style (flat-bottom) crucibles for thermal analysis setups

-Shallow or deep bowl crucibles

-Covered crucibles with matching lids

-Custom Quartz crucibles as per customer drawings or designs:

Custom dimensions and special shapes are commonly offered to suit unique process requirements.