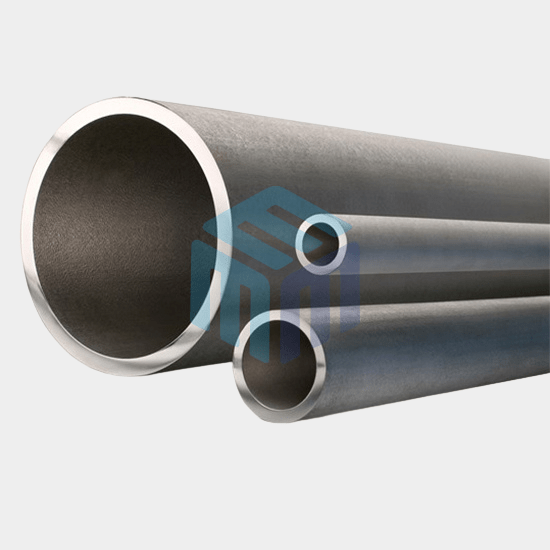

Silicon Carbide Tubes, Silicon Carbide Pipes and Silicon Carbide Rods (SiC Tubes, SiC Pipes and SiC Rods)

Inquiry NowProduct Description

General Description:

Material: Silicon carbide (SiC) tubes and rods are ceramic products made from silicon carbide, a compound consisting of silicon and carbon.

SiC is known for its exceptional mechanical strength, high thermal conductivity, excellent thermal shock resistance, and resistance to wear, corrosion, and extreme temperatures. SiC tubes and rods find applications in industries such as aerospace, automotive, chemical, and semiconductor manufacturing.

It can be produced in different forms, such as reaction-bonded silicon carbide (RB-SiC), sintered silicon carbide (SSiC), or recrystallized silicon carbide (RSiC). These forms have varying manufacturing processes and properties.

Manufacturing Process: The manufacturing process for silicon carbide tubes and rods can vary depending on the specific form:

-

- Reaction-bonded silicon carbide (RB-SiC): This process involves infiltrating molten silicon into a porous carbon preform, which reacts with carbon to form silicon carbide in situ.

Operating temperature range: Typically up to approximately 1600-1700°C (2912-3092°F)

Maximum temperature for short-term use: Around 1800-1900°C (3272-3452°F)

RbSiC exhibits good thermal stability and can withstand rapid temperature changes, making it suitable for high-temperature applications.

-

- Sintered silicon carbide (SSiC): SSiC is produced by sintering a mixture of silicon carbide powder and a small amount of sintering aids at high temperatures.

Operating temperature range: Typically up to approximately 1600-1800°C (2912-3272°F)

Maximum temperature for short-term use: Around 1800-1900°C (3272-3452°F)

SSiC exhibits exceptional mechanical strength and can withstand high temperatures while maintaining its structural integrity.

-

- Recrystallized silicon carbide (RSiC): RSiC is made by heating a mixture of silicon carbide and carbon at high temperatures, causing the silicon carbide to recrystallize and form a dense, interconnected structure.

Operating temperature range: Typically up to approximately 1500-1600°C (2732-2912°F)

Maximum temperature for short-term use: Around 1650-1700°C (3002-3092°F)

RSiC demonstrates excellent thermal shock resistance and retains its mechanical properties at high temperatures

Dimensions: Silicon carbide tubes and rods come in various dimensions, including outer and inner diameters, wall thicknesses, and lengths. They can be customized to meet specific application requirements.

Silicon carbide tubes and rods can be customized with features such as flanges, threads, or grooves to facilitate connections and installations.

It’s important to note that the specific properties, dimensions, and manufacturing processes of silicon carbide tubes and rods can vary based on the manufacturer and the intended application. Therefore, it’s advisable to consult the M-Kube team for detailed specifications and recommendations based on your specific needs.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, Philippines and Vietnam. We are forefront of scientific laboratory consumables supply, providing a range of high-purity silicon carbide crucibles, silicon carbide foam filter, silicon carbide heating elements or SiC heating elements, all available in various sizes (diameter, thickness, and length) to cater to the diverse needs of chemistry and science laboratories. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.

Properties:

Silicon carbide tubes and rods possess several desirable properties, including:

-

- High mechanical strength: SiC has excellent mechanical properties, including high hardness, stiffness, and strength, making it suitable for demanding applications with high erosion and abrasive resistance requirements.

- High thermal conductivity: SiC exhibits high thermal conductivity, allowing for efficient heat transfer.

- Exceptional thermal shock resistance: SiC can withstand rapid temperature changes without cracking or significant damage.

- Excellent chemical resistance: SiC is highly resistant to a wide range of chemicals, acids, and corrosive environments.

- High-temperature resistance: SiC retains its mechanical properties at elevated temperatures and can withstand temperatures up to around 1600°C.

- Low coefficient of thermal expansion: SiC has a low thermal expansion coefficient, providing dimensional stability in high-temperature applications.

Applications:

Silicon carbide tubes and rods are used in various industries and applications, including:

-

- Kilns and furnaces: SiC tubes and rods are used as components in high-temperature furnaces, kilns, and other thermal processing equipment.

- Semiconductor manufacturing: SiC is utilized in the production of power electronic devices and components due to its high-temperature stability and electrical properties.

- Chemical processing: SiC tubes and rods are resistant to corrosive chemicals and find applications in chemical reactors, heat exchangers, and pipes. As thermocouple protectors, spray nozzles, shot blast nozzles, cyclone components etc.

- Aerospace and automotive: SiC components are used in aerospace and automotive industries for their lightweight, high-strength, and high-temperature resistance properties.

- Energy applications: SiC tubes and rods are employed in energy systems such as solar thermal power plants and nuclear reactors due to their thermal and chemical stability.

- Wear and erosion protection: SiC is used as a protective lining in equipment exposed to abrasive materials or erosive environments.