Tantalum Crucible

Inquiry NowProduct Description

Tantalum crucible is inactive to the majority of the elements and compounds. It is resistant to corrosion and most of the acids. It is non-reactive to most of the gases and less reactive to alkaline solutions. Heating and vaporisation parts are usually made up of tantalum because it has high resistance to high temperature and low vapour pressure.

Tantalum crucible, made up of tantalum, a blue-grey metal. It is extremely heavy, ductile, hard, and has the fourth highest melting point of all metals. Tantalum crucibles come in a variety of shapes and sizes available as per the requirements.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at [email protected] or call us at +1-732-808-1999 to discuss your projects.

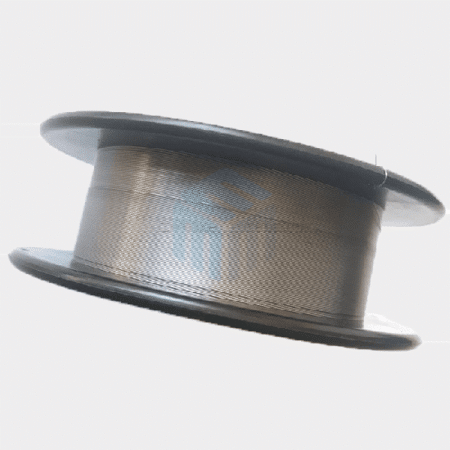

We also provide Tantalum Wires, Tantalum Rods and Tubes, and Tantalum substrates.

Key properties

- High melting point 3017 °C

- High boiling point 5458 °C

- Material strength

- Chemically stable

- Chemically inert

- High density

- High resistance to corrosion

- Ductile

Application

Tantalum crucible’s properties like high temperature resistance, resistance to corrosion chemical stability and chemical inertness, makes it the perfect material to be used in various industrial and laboratory applications. It is used: –

- As a substitute for platinum

- For creating superalloys and electron-beam melting

- In metallurgical industries

- For machinery processing

- For glass, and ceramic industries

Frequently Asked Questions:

Why is Tantalum used to make Crucibles?

Tantalum is chosen for crucible applications due to its exceptional resistance to high temperatures and chemical corrosion. A high purity tantalum crucible provides clean performance in sensitive environments, such as crystal growth or metal processing, where material purity is critical.

How does a Tantalum Crucible perform in high temperatures?

Tantalum crucibles can handle extreme heat—up to 3,000°C in vacuum settings. When used as a tantalum crucible for vacuum furnace operations, they maintain structural integrity and stability, even under thermal cycling, making them ideal for high-temperature research and production.

Is a Tantalum Crucible chemically resistant?

Yes, tantalum is highly inert and resists corrosion from acids like hydrochloric and sulfuric acid. This chemical resistance allows high purity tantalum crucibles to be used in aggressive chemical environments without degrading or contaminating materials.

Can I use tantalum crucibles for melting metals?

Yes, tantalum crucibles can be used for melting metals. They are highly resistant to heat, corrosion, and chemical reactions, making them suitable for high-temperature metal melting and refining processes. However, due to their high cost, they are typically used for specialized applications where their unique properties are essential. Always ensure the crucible material is compatible with the specific metals and temperatures involved in your process

What sizes and shapes are available for tantalum crucibles?

Tantalum crucibles come in a variety of standard forms such as cylindrical or conical, and can also be custom-made. A reliable tantalum crucible supplier in USA, like M-Kube Enterprise, can accommodate specific size, shape, and thickness requirements for your process or furnace design.

Is tantalum safe to handle?

Yes, tantalum is considered safe and non-toxic. Its biocompatibility makes it suitable not only in lab use but also in medical applications. Proper handling guidelines should still be followed, especially when working with a tantalum crucible in high-temperature environments.