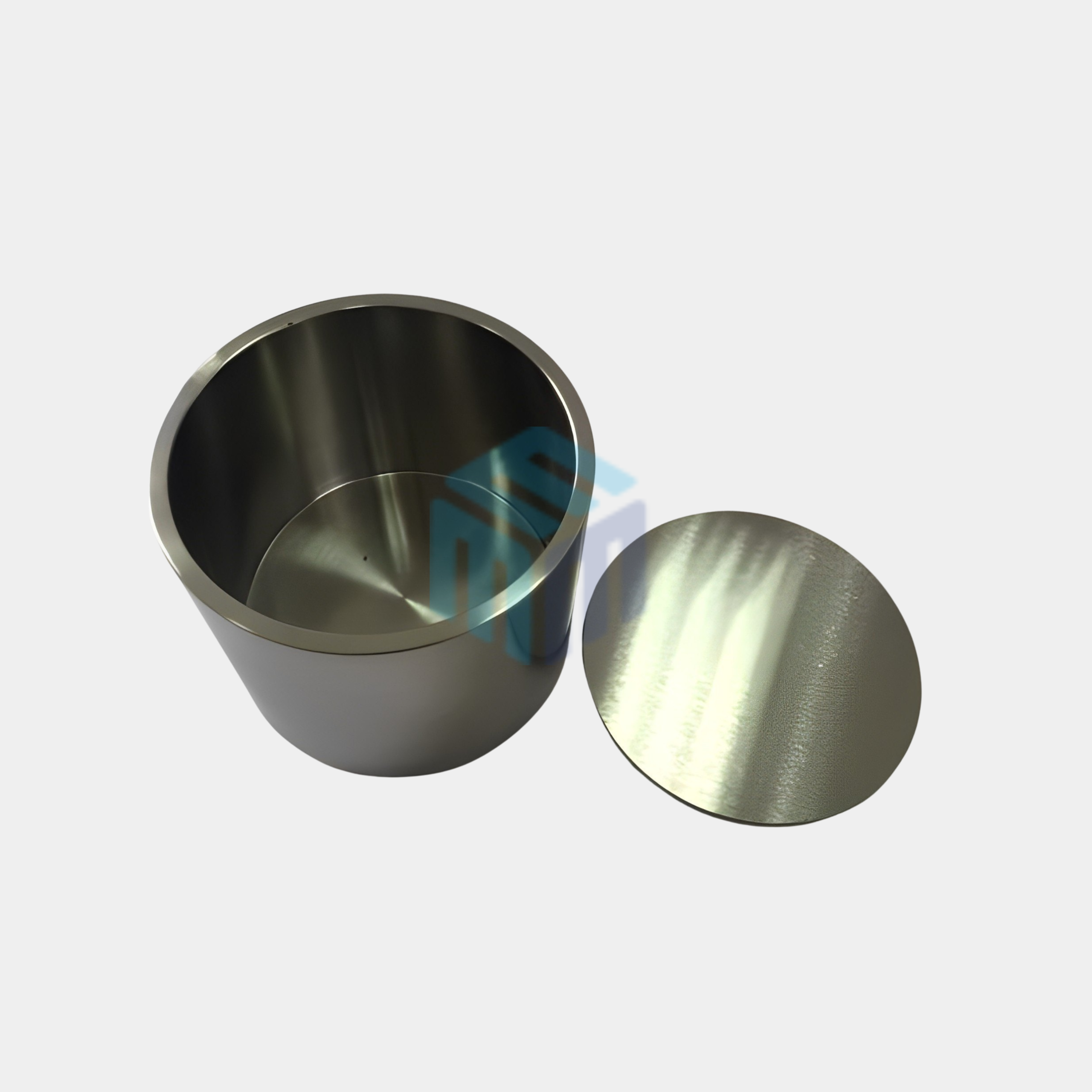

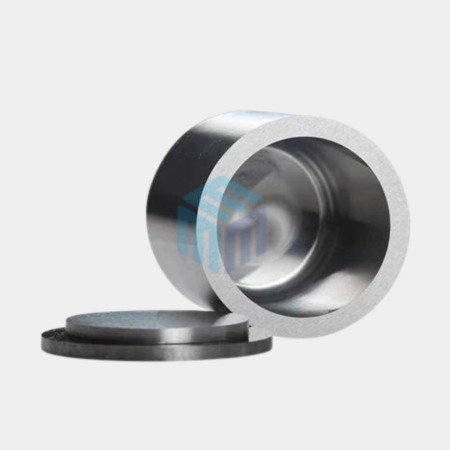

Tungsten Carbide Crucibles

Inquiry NowProduct Description

Tungsten carbide crucibles are specialized containers or vessels made from tungsten carbide (WC) materials. They are designed for use in high-temperature and demanding environments, especially in laboratories, research, and industrial processes where extreme conditions are present. Tungsten carbide crucibles have several unique properties that make them suitable for specific applications:

- High-Temperature Resistance: Tungsten carbide can withstand extremely high temperatures, making it ideal for applications involving the melting, sintering, or heat treatment of materials with high melting points.

- Excellent Thermal Shock Resistance: Tungsten carbide crucibles are known for their exceptional thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or breaking.

- Chemical Inertness: Tungsten carbide is chemically inert to many substances, making it well-suited for use with reactive materials and in applications where chemical resistance is important.

- High Hardness and Wear Resistance: Tungsten carbide is exceptionally hard and wear-resistant, ensuring long-lasting durability in applications where abrasion and wear are common.

Tungsten carbide crucibles find various applications, including:

- Metallurgy: Tungsten carbide crucibles are used in the melting and casting of metals with high melting points, such as tungsten, tantalum, and molybdenum. They are essential in the production of alloys, superalloys, and refractory metals.

- Ceramic and Glass Processing: Tungsten carbide crucibles are employed in the production of ceramics and glass, including the melting and crystallization of glass materials.

- Laboratory and Research: They are used in laboratories and research facilities for high-temperature sample preparation, thermal analysis, and material research.

- Semiconductor Manufacturing: Tungsten carbide crucibles are utilized in the growth of single crystals and the deposition of semiconductors in the electronics industry.

- Powder Metallurgy: They are used in the sintering of hard metals, carbides, and ceramics in the powder metallurgy process.

- Chemical Processing: Tungsten carbide crucibles find application in chemical reactions and materials testing that require resistance to harsh chemical environments.

- Precious Metal Analysis: They are used in the analysis of precious metals due to their high-temperature stability and chemical inertness.

- High-Temperature Furnace Applications: Tungsten carbide crucibles are employed in high-temperature environments for various heat treatment and materials processing applications.

Tungsten carbide crucibles come in various shapes and sizes to suit different applications and can be customized to meet specific requirements, such as crucible dimensions, lids, and coatings. When selecting a tungsten carbide crucible for a particular application, it’s important to consider factors like the required temperature range, chemical compatibility, and the volume of material to be processed. Proper handling and care are essential to avoid thermal shock and maintain the crucible’s integrity.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.