Tungsten Carbide Customization Applications

Inquiry NowProduct Description

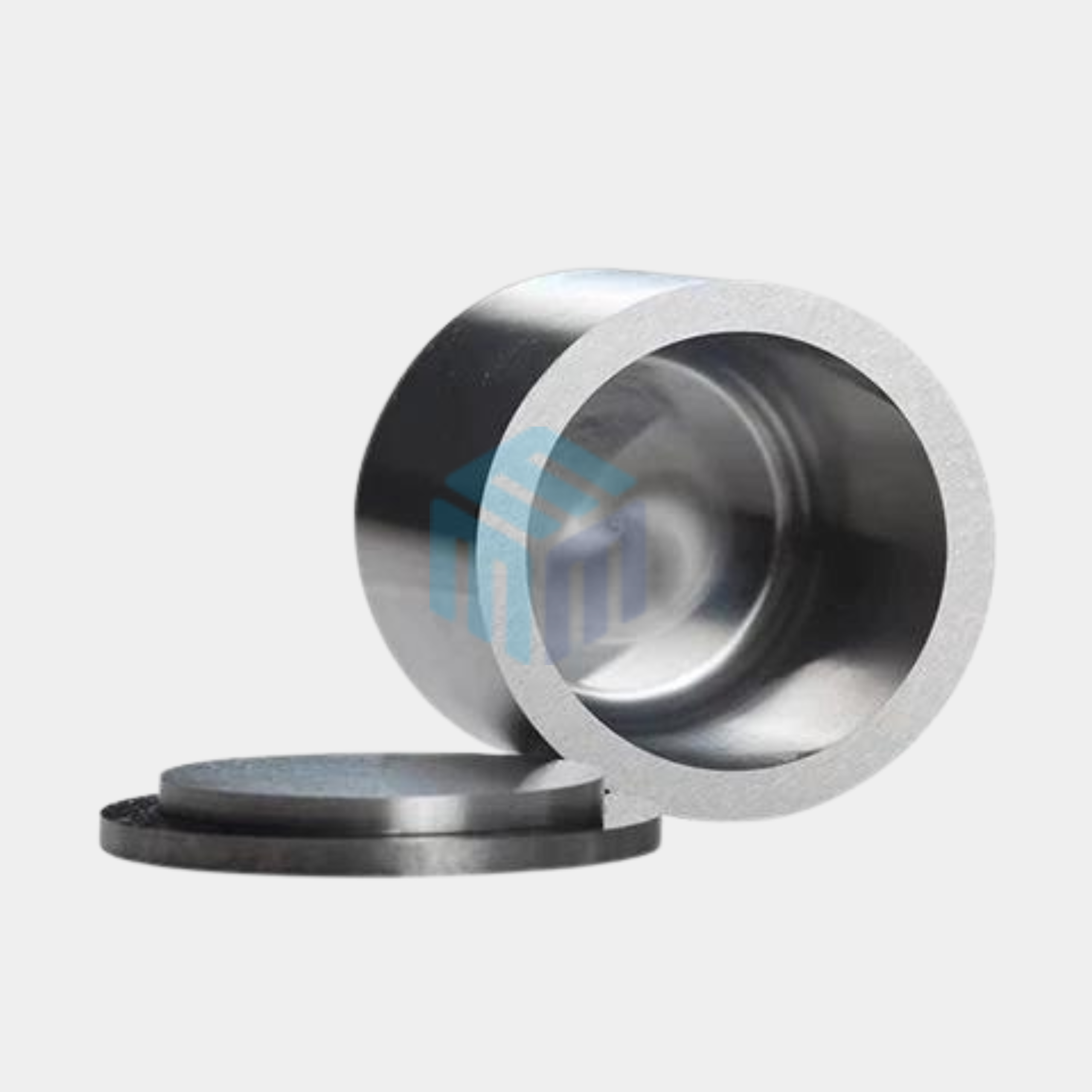

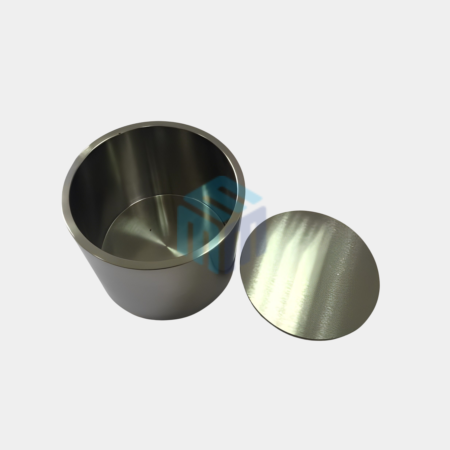

Tungsten carbide is a hard and wear-resistant material known for its excellent strength, toughness, and resistance to abrasion and high temperatures. Customization in tungsten carbide applications is often essential to meet specific requirements for various industries. Here are some common applications and ways in which tungsten carbide can be customized:

- Cutting Tools: Customized tungsten carbide cutting tools can be tailored for specific applications, such as milling, drilling, turning, and grinding. Customization may involve tool geometries, grades, coatings, and cutting parameters.

- Wear Parts and Wear Liners: Tungsten carbide wear parts are used in industries like mining, construction, and agriculture. Customization can involve designing parts with specific shapes, sizes, and carbide grades to optimize wear resistance and longevity.

- Metal Forming and Stamping: Customized tungsten carbide dies, punches, and tooling are used in metal forming and stamping processes. Customization may include die designs, surface finishes, and dimensions for precision metal shaping.

- Woodworking Tools: Tungsten carbide inserts and tips are used in woodworking tools like saw blades, planer knives, and router bits. Customization can involve tool geometry and carbide grade selection for different woodworking tasks.

- Oil and Gas Drilling: Customized tungsten carbide nozzles, buttons, and inserts are used in drilling tools for the oil and gas industry. Customization may include specific designs and carbide grades for improved drilling performance.

- Industrial and Mining Equipment: Tungsten carbide components are used in mining and industrial equipment, including cutting picks, drilling bits, and wear-resistant components. Customization may involve component designs and carbide compositions to withstand harsh conditions.

- Bearing Balls and Components: Tungsten carbide balls and components are used in bearing and valve applications. Customization can involve ball sizes, surface finishes, and material grades to enhance performance and durability.

- Powder Metallurgy: Tungsten carbide powders are used in powder metallurgy processes to produce various components. Customization may include powder compositions, particle sizes, and sintering conditions for specific part properties.

- Agricultural Tools: Tungsten carbide inserts are used in agricultural tools, such as plowshares and cultivator points. Customization may involve insert shapes and materials to improve soil penetration and wear resistance.

- Rotary Cutting Tools: Customized tungsten carbide rotary cutting tools are used in dental, medical, and industrial applications. Customization may involve specific tool designs and cutting edge geometries.

- Wire Drawing Dies: Tungsten carbide wire drawing dies are used in the manufacturing of wires and cables. Customization can involve die designs, profiles, and materials for specific wire drawing processes.

To achieve customization in tungsten carbide applications, it is important to work with manufacturers or suppliers specializing in precision tungsten carbide production and processing. These experts can assist in the design, engineering, and production of tungsten carbide components and materials to meet specific material properties, geometrical dimensions, surface finishes, and functional requirements, ensuring that the final product aligns with the intended application. Customization is crucial to optimize the performance and longevity of tungsten carbide in various industrial and technological sectors.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.