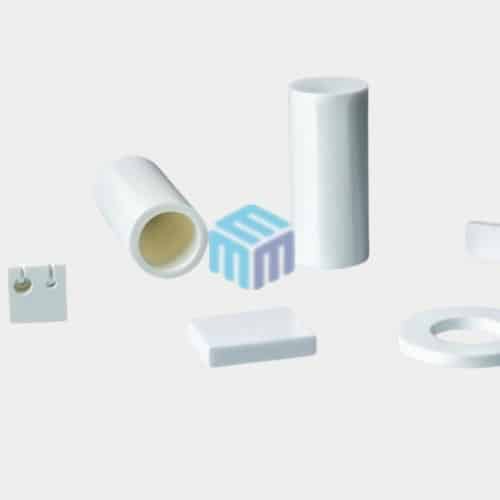

Zirconia Customization Applications

Inquiry NowProduct Description

Zirconia, also known as zirconium dioxide (ZrO2), is a versatile ceramic material with excellent mechanical, thermal, and chemical properties. Customization in zirconia applications is often necessary to meet specific requirements for a wide range of industries. Here are some common applications and ways in which zirconia can be customized:

- Dental Implants and Prosthetics: Customized zirconia dental implants and crowns are designed to match the patient’s anatomy and cosmetic preferences. The customization may include precise shaping, sizing, and shade matching.

- Medical Devices: Zirconia is used in medical devices, such as surgical tools, orthopedic components, and hearing aid shells. Customization may involve the design of specific shapes, sizes, and biocompatible coatings.

- Ball Bearings and Ball Valves: Zirconia is used in ball bearings and ball valves for its high wear resistance. Customization can involve designing ball bearings with specific tolerances, dimensions, and surface finishes for different applications.

- Ceramic Coatings: Customized zirconia coatings can be applied to various substrates to enhance wear resistance, corrosion resistance, and thermal insulation properties. The customization includes coating thickness and composition.

- Cutting Tools and Blades: Customized zirconia cutting tools and blades are used in various industries, including machining, cutting, and grinding. The customization may include the design of specific geometries and compositions for optimal cutting performance.

- Abrasives: Zirconia abrasives are used in sandpapers, grinding wheels, and belts. Customization can involve the choice of abrasive grit sizes, bonding agents, and backing materials for different applications.

- Thermal Barrier Coatings: Zirconia-based coatings are used as thermal barrier coatings in gas turbine engines. Customization may involve the design of coatings with specific thermal properties and layer thicknesses.

- Solid Oxide Fuel Cells (SOFCs): Customized zirconia electrolyte materials are used in SOFCs for power generation. The customization may include the development of specific compositions and microstructures to enhance performance.

- Sensor Components: Zirconia-based components are used in gas sensors and oxygen sensors. Customization can involve designing sensor structures and materials for specific sensing applications.

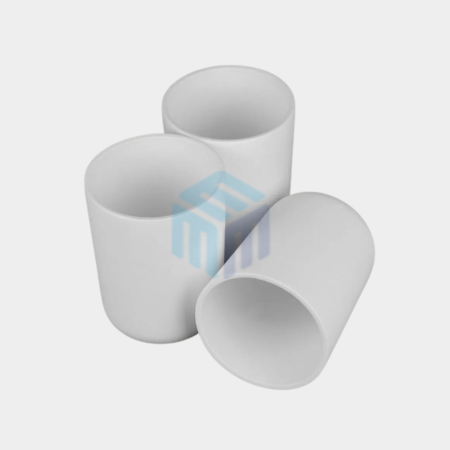

- High-Temperature Crucibles and Labware: Customized zirconia crucibles and labware are used in high-temperature applications, such as materials research and analysis. The customization can involve precise dimensions and purity levels.

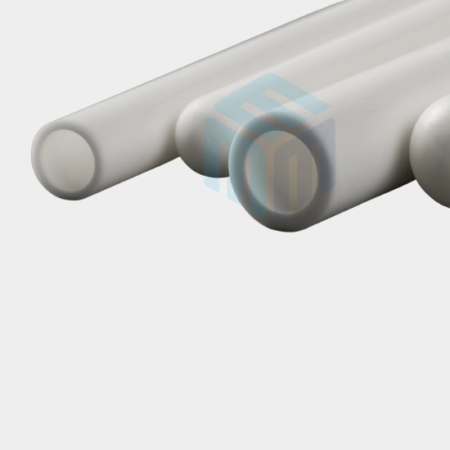

- Thermocouple Protection Tubes: Customized zirconia thermocouple protection tubes are designed to protect temperature sensors in harsh environments. The customization may include dimensions and material purity.

- Ceramic Bearings: Zirconia bearings can be customized for use in precision instruments and machines. The customization involves size, tolerances, and material composition for specific applications.

To achieve customization in zirconia applications, it is important to work with manufacturers or suppliers specializing in precision zirconia fabrication. These experts can assist in the design, engineering, and production of zirconia components to meet specific material properties, geometrical dimensions, surface finishes, and functional requirements, ensuring that the final product aligns with the intended application. Customization is crucial to optimize the performance and functionality of zirconia in various industrial and technological sectors.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, Dubai, the Philippines, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at info@mkubeenterprise.com or call us at +1-732-808-1999 to discuss your projects.