Alumina tubes are essential components in high-temperature applications such as tube furnaces. However, many labs and industrial users face a common challenge: unexpected tube breakage. This blog explores why alumina tubes break, how to prevent it, and how to extend their lifespan — especially for users sourcing from alumina tube suppliers in the USA.

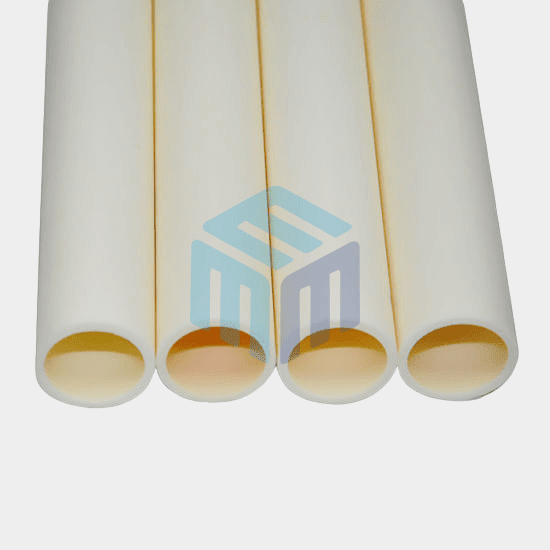

What Are Alumina Tubes?

Alumina tubes are ceramic tubes made primarily from aluminum oxide (Al₂O₃), typically in purities of 95–99.8%. Known for their high temperature resistance, excellent electrical insulation, and corrosion resistance, high alumina ceramic tubes are widely used in thermal processing equipment, such as alumina tube furnaces.

These tubes are commonly used in:

- Heat treatment

- Gas flow control systems

- Thermocouple protection

- Laboratory-scale sintering and annealing

Why Are They Critical in Tube Furnaces?

In alumina tube furnaces, the tube serves as the core reaction zone or heating chamber. It is exposed to thermal cycling, mechanical stress, and chemical environments. As such, the performance and durability of the alumina furnace tube directly affect the reliability and cost-efficiency of your thermal processing.

The Problem of Tube Breakage and Its Impact

When an alumina tube fails, it can:

- Contaminate valuable samples

- Damage heating elements or insulation

- Lead to costly downtime

- Pose safety risks in high-temperature setups

Understanding why these tubes break helps you take preventive measures and choose the right specifications from trusted alumina tube suppliers.

Common Reasons Alumina Tubes Break in Tube Furnaces

- Thermal Shock

Rapid temperature changes cause internal stresses that can fracture the tube. Avoid inserting cold samples into a hot tube or heating too quickly. - Improper Mounting

Uneven support or excessive clamping pressure can create stress points, leading to cracks under heat. - Atmosphere-Induced Degradation

Prolonged exposure to certain gases (e.g., hydrogen, moisture) may degrade the tube’s surface and structure over time. - Mechanical Stress or Impact

Mishandling during installation or removal is a frequent cause of microcracks that grow with use. - Overheating Beyond Rated Temperature

Exceeding the maximum operating temperature weakens the ceramic and accelerates failure. - Poor Quality or Low-Purity Tubes

Choosing low-grade tubes from unreliable alumina ceramic tube suppliers can result in early failure, especially under harsh conditions.

Signs Your Alumina Tube Is About to Fail

Alumina tubes are widely used in high-temperature applications due to their excellent thermal stability, corrosion resistance, and mechanical strength. However, like all ceramic materials, they are prone to wear and eventual failure when exposed to prolonged thermal and mechanical stress. Identifying early signs of failure is crucial for maintaining process efficiency, preventing costly damage, and ensuring workplace safety. Below are some key indicators that your alumina tube may be approaching the end of its service life:

1. Visible Cracks or Fractures

Cracks—whether hairline or more pronounced—are among the most obvious signs of impending failure. These can form due to repeated thermal cycling, mechanical stress, or improper handling. Even small cracks can rapidly propagate under high-temperature conditions, leading to sudden failure.

2. Discoloration or Surface Degradation

Changes in the color or texture of the alumina tube’s surface may indicate chemical reactions or corrosion, especially when exposed to aggressive gases or vapors. Surface dullness, pitting, or chalky residues can also suggest structural weakening.

3. Spalling or Flaking

Spalling—when pieces of the ceramic surface begin to flake off—indicates thermal stress or incompatible material interactions. It often results from rapid heating or cooling, which creates uneven expansion and contraction.

4. Warping or Deformation

Although alumina is a rigid material, prolonged exposure to extreme temperatures beyond its design limits can cause slight warping. This deformation compromises alignment and structural integrity, especially in precision systems like furnaces or reactors.

5. Unusual Temperature Readings

If your temperature sensors start showing inconsistent or unexpected values, it could point to developing faults in the alumina tube. Cracks or thinning walls can affect heat distribution and thermal conductivity.

6. Contamination or Material Build-up

Deposits or residues inside or outside the tube may indicate material incompatibility or leakage through micro-cracks. Over time, these deposits can further stress the tube and accelerate degradation.

7. Reduced Mechanical Strength

While this isn’t always visible, tubes may become more brittle over time. A tube that was once resilient to minor handling impacts may start showing chips or break easily with minimal force.

How to Prevent Alumina Tube Breakage in Tube Furnaces

Alumina tubes are commonly used in tube furnaces for their excellent thermal and chemical resistance. However, improper handling or operating conditions can lead to premature breakage, causing costly delays and equipment damage. Here are key strategies to prevent alumina tube breakage in tube furnaces:

1. Avoid Thermal Shock

Alumina is highly resistant to heat but vulnerable to thermal shock, which occurs when the tube is exposed to sudden temperature changes.

Solution:

- Heat and cool the furnace gradually.

- Use a ramped heating program rather than an immediate high-temperature start.

- Preheat samples before placing them inside the hot tube.

2. Ensure Even Temperature Distribution

Uneven heating can create stress points within the tube, leading to cracks or warping.

- Solution:

- Use a well-calibrated furnace with uniform temperature zones.

- Avoid placing samples too close to the tube walls or furnace ends.

3. Use Proper Tube Supports

Unsupported or poorly supported tubes can sag or break under their own weight when heated.

- Solution:

- Install appropriate tube supports or saddles, especially for longer tubes.

- Position supports outside the hot zone to prevent material weakening.

4. Avoid Mechanical Stress and Impact

Alumina is brittle and can crack easily from accidental bumps or improper installation.

- Solution:

- Handle tubes with care during installation, maintenance, or cleaning.

- Use padded gloves and non-metallic tools when inserting or removing tubes.

- Ensure proper alignment when mounting the tube to avoid stress points.

5. Use Compatible Gaskets and Seals

Improper sealing can create pressure imbalances or chemical reactions that damage the tube.

- Solution:

- Choose seals and flanges that are chemically and thermally compatible with alumina.

- Avoid over-tightening, which can crack the ends of the tube.

6. Protect Against Chemical Attack

Certain gases or molten materials can react with alumina, weakening its structure over time.

- Solution:

- Know your process chemistry and confirm alumina’s compatibility.

- Use liners or protective coatings if aggressive chemicals are involved.

7. Regular Inspection and Maintenance

Undetected cracks or wear can lead to sudden failure during operation.

- Solution:

- Perform routine visual inspections for cracks, discoloration, or deformation.

- Replace tubes showing signs of wear before catastrophic failure occurs.

Expert Recommendations for Maximizing Alumina Tube Lifespan

- Stick to the manufacturer’s rated maximum temperature (typically 1600–1800°C for high alumina tubes).

- Rotate the tube periodically to distribute wear.

- Replace tubes showing microcracks or signs of fatigue.

- Store tubes in dry, cushioned environments when not in use.

- Choose alumina furnace tubes that match the specific chemistry of your furnace atmosphere.

Read also: Choosing the Right Alumina Tube for Your Application

Conclusion

Alumina tubes are engineered for strength, but they aren’t indestructible. Breakage is usually preventable with careful handling, proper installation, and by sourcing high-purity tubes from reliable alumina ceramic tube suppliers. Understanding why they fail helps you save time, money, and resources in your lab or industrial process.

If you’re looking for alumina tubes in Australia or the USA, M-Kube Enterprise provides premium-grade high alumina ceramic tubes designed for demanding thermal environments.

FAQs

Can alumina tubes be reused?

Yes, if the tube shows no cracks, wear, or surface degradation. Always inspect before reuse.

What is the maximum safe operating temperature?

Typically between 1600°C and 1800°C, depending on the purity and manufacturer.

How long should a well-maintained alumina tube last?

With proper care, a high-purity alumina tube can last hundreds of heating cycles, depending on the application and conditions.