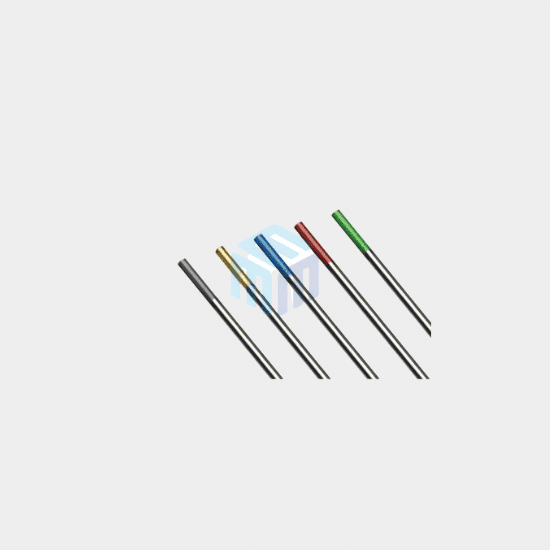

Tungsten electrodes are a critical component in TIG (Tungsten Inert Gas) welding and other high-temperature applications, valued for their exceptional heat resistance, conductivity, and durability. Available in various types such as pure tungsten, thoriated, ceriated, and lanthanated, these electrodes are chosen based on the specific requirements of the welding process. However, like any material, tungsten electrode come with both benefits and limitations. In this blog, we’ll explore the key advantages and disadvantages of tungsten electrode to help you make an informed choice for your industrial or laboratory needs.

Here are the key advantages and disadvantages of tungsten electrodes:

Tungsten electrodes are widely used in various applications, particularly in welding processes like Gas Tungsten Arc Welding (GTAW or TIG welding).

Advantages of Tungsten Electrodes

Tungsten electrodes are favored in welding and high-temperature applications due to their strength and performance under extreme conditions. Their unique properties contribute to cleaner welds and longer electrode life. Here are the key advantages of tungsten electrode:

High Melting Point:

-

- Advantage: Tungsten has an exceptionally high melting point (3422°C or 6192°F).

- Benefit: This makes tungsten electrode ideal for welding applications as they can withstand high temperatures without melting.

Excellent Electrical Conductivity:

-

- Advantage: Tungsten exhibits good electrical conductivity.

- Benefit: Provides stable and consistent arc performance, essential for high-quality welding.

High Arc Stability:

-

- Advantage: Tungsten electrode offer stable arc characteristics.

- Benefit: Ensures precision and control in welding, leading to high-quality welds with minimal spatter.

Durability and Wear Resistance:

-

- Advantage: Tungsten is very hard and resistant to wear.

- Benefit: Tungsten electrode have a long lifespan, reducing the frequency of electrode replacement.

Minimal Contamination:

-

- Advantage: Tungsten electrode produce minimal contamination during welding.

- Benefit: Results in cleaner welds, which is particularly important in applications requiring high purity, such as aerospace and nuclear industries.

Versatility:

-

- Advantage: Tungsten electrode can be used for welding a variety of metals, including steel, stainless steel, and non-ferrous metals.

- Benefit: Provides flexibility in different welding applications.

Disadvantages of Tungsten Electrodes

While tungsten electrodes offer many advantages, they also come with certain limitations that users should consider. These drawbacks can impact safety, cost, and application-specific performance.

Here are the main disadvantages of tungsten electrodes:

- Brittleness: Tungsten is relatively brittle compared to other metals, making the electrodes prone to cracking or breaking if mishandled.

- Health Hazards: Thoriated tungsten electrodes (which contain thorium) can pose health risks due to radioactive exposure. Special handling and disposal are required to mitigate these risks.

- Cost: Tungsten electrodes can be more expensive than other types of electrodes due to the material costs and manufacturing processes.

- Special Equipment Needed: Using tungsten electrode, especially in TIG welding, requires specialized welding equipment and expertise, which might increase the initial setup cost.

- Contamination Sensitivity: While tungsten itself is resistant to contamination, the welding process can be sensitive to contaminants on the electrode surface, necessitating careful cleaning and preparation.

- Limited Alloy Compatibility: Tungsten electrode may not be suitable for welding certain alloys or metals that require specific electrode materials for optimal results.

By weighing these advantages and disadvantages, you can determine if tungsten electrodes are the right choice for your specific welding needs and applications.

Conclusion:

Tungsten electrodes play a vital role in precision welding and high-temperature applications due to their durability, excellent conductivity, and ability to maintain shape under extreme heat. While they offer significant advantages such as clean, stable arcs and long service life, users should also be aware of their disadvantages—including brittleness, potential health risks with certain types, and higher costs.

Choosing the right type of tungsten electrode depends on your specific application, welding environment, and safety requirements. By understanding both the benefits and limitations, you can make informed decisions that optimize performance and ensure safe, efficient operation.

M-Kube Enterprise is a USA company catering customized laboratory products, laboratory consumables, and laboratory solutions in the USA, India, Australia, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.