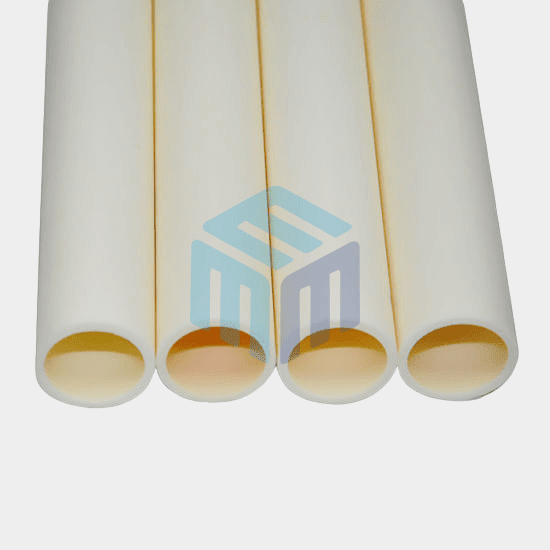

Alumina tubes are essential components in a wide range of high-temperature and corrosive environments, widely used in laboratories, industrial furnaces, and research settings. Known for their excellent thermal stability, mechanical strength, and resistance to chemical attack, these ceramic tubes are valued for their performance under extreme conditions. In this blog, we’ll explore the key properties of alumina tubes, their common applications, and essential maintenance tips to help extend their service life and ensure optimal functionality. Whether you’re sourcing materials or looking to improve system longevity, this guide provides practical insights for every user.

Properties of Alumina Tubes:

Alumina tubes, also known as ceramic tubes or alumina oxide tubes, are widely used in various industries and applications due to their excellent properties. Here are the key properties, uses, and maintenance tips for alumina tubes:

- High-Temperature Resistance: Alumina tubes can withstand high temperatures, typically up to 1700°C (3092°F) or higher, depending on the grade of alumina used. This makes them suitable for thermal processes such as heating, sintering, and annealing. For reliable sourcing, consider reputable Alumina Tube Suppliers in USA to ensure quality and timely delivery.

- Chemical Inertness: Alumina is chemically inert and resistant to most acids, alkalis, and corrosive substances. Alumina tubes are therefore used in environments where chemical resistance is crucial, such as in laboratories, chemical plants, and semiconductor manufacturing.

- Electrical Insulation: Alumina is an excellent electrical insulator, making alumina tubes suitable for applications involving high-voltage equipment, electrical insulation, and semiconductor processing.

- Mechanical Strength: Alumina tubes exhibit high mechanical strength and hardness, providing resistance to mechanical wear, abrasion, and impact. This property contributes to their durability and longevity.

- Thermal Conductivity: While alumina is not as thermally conductive as metals, it still has moderate thermal conductivity. This property allows for efficient heat transfer in thermal processes while maintaining thermal insulation.

- Low Thermal Expansion: Alumina has a low coefficient of thermal expansion, meaning alumina tubes experience minimal dimensional changes with temperature fluctuations. This property helps prevent thermal stress-induced cracking.

Uses of Alumina Tubes:

Alumina tubes are widely chosen for their superior resistance to heat and corrosion, making them ideal for demanding environments. Their structural integrity and insulating properties enable reliable performance in both scientific and industrial applications. Below are some of the most common uses of alumina tubes:

- Furnace Tubes: Alumina tubes are commonly used as furnace tubes in high-temperature furnaces for heat treatment, sintering, and thermal processing of materials such as metals, ceramics, and composites.

- Thermocouple Protection Tubes: Alumina tubes are used to protect thermocouples in industrial processes where temperature measurement is critical. The high-temperature resistance and thermal insulation properties of alumina help maintain accurate temperature readings.

- Semiconductor Processing: Alumina tubes are utilized in semiconductor manufacturing processes for components such as diffusion tubes, wafer boats, and insulating sleeves. They provide electrical insulation and withstand the harsh conditions of semiconductor fabrication.

- Chemical Industry: Alumina tubes find applications in the chemical industry for handling corrosive chemicals, acids, and alkalis. They are used as reaction vessels, sample tubes, and liners in chemical processing equipment.

- Laboratory Equipment: Alumina tubes are used in laboratory settings for various applications, including thermal analysis, sample containment, and experimental setups requiring high-temperature resistance and chemical inertness.

Read also: How to use Alumina Tubes at high temperature for long-term use?

Maintenance Tips for Alumina Tubes:

Proper maintenance of alumina tubes is essential to ensure their long-lasting performance and reliability. Regular cleaning, careful handling, and avoiding sudden temperature changes can prevent damage and extend the tube’s service life. Here are some key maintenance tips for alumina tubes:

- Cleaning: Regularly clean alumina tubes to remove deposits, residues, and contaminants that can affect their performance. Use appropriate cleaning agents compatible with alumina.

- Avoid Thermal Shock: Alumina tubes should be gradually heated or cooled to avoid thermal shock, which can lead to cracking. Use proper heating and cooling rates in thermal processes.

- Handle with Care: Handle alumina tubes carefully to prevent mechanical damage. Avoid dropping or impacting the tubes, especially at elevated temperatures.

- Inspect for Damage: Periodically inspect alumina tubes for signs of damage, such as cracks, chips, or wear. Replace damaged tubes to ensure continued performance and safety.

- Storage: Store alumina tubes in a clean and dry environment to prevent contamination and moisture absorption. Use protective packaging or racks to avoid physical damage during storage.

By understanding the properties, uses, and maintenance tips for alumina tubes, you can ensure their optimal performance and longevity in various industrial, laboratory, and scientific applications.

Conclusion:

In conclusion, alumina tubes are valued for their exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for demanding laboratory and industrial applications. With proper care and maintenance, these tubes can offer long service life and consistent performance. If you’re looking for high-quality products, choosing a trusted alumina tubes and rods supplier in the USA is essential. Suppliers like M-Kube Enterprise provide reliable, lab-grade ceramic solutions tailored to your specific needs.

M-Kube Enterprise is a USA company catering customized laboratory products, laboratory consumables, and laboratory solutions in India, Australia, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.