Alumina tubes are essential components in a wide range of high-temperature and corrosive applications—from industrial furnaces and thermocouple protection to chemical processing and laboratory use. Known for their excellent thermal stability, mechanical strength, and resistance to chemical attack, alumina ceramic tubes offer reliable performance in even the most demanding environments. However, with various grades, dimensions, and design options available, selecting the right alumina tube for your specific application can be challenging. In this guide, we’ll walk you through the key factors to consider—such as purity level, size, and operating conditions—so you can make an informed decision that maximizes efficiency and longevity.

Purity of Alumina

- 99.8% Alumina: Offers excellent mechanical strength, high thermal conductivity, and resistance to wear and chemical attack. Suitable for high-temperature and high-pressure applications.

- 99.5% Alumina: Commonly used for general-purpose applications, where slightly lower purity and performance are acceptable.

- 95% Alumina: More affordable, with good mechanical properties, but lower thermal and chemical resistance. Used in less demanding applications.

Temperature Tolerance

- Alumina tubes are known for their high-temperature resistance, often up to 1,700°C or higher. Ensure that the tube’s maximum operating temperature aligns with your application’s requirements.

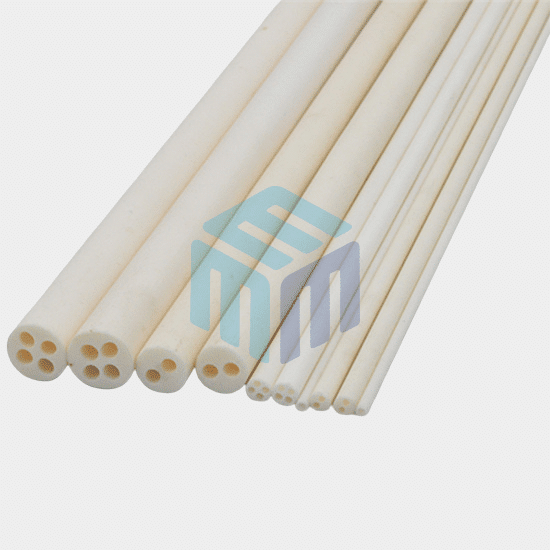

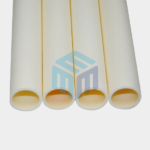

Dimensional Specifications

- Inner and Outer Diameters: Choose the correct dimensions to fit your equipment or system.

- Wall Thickness: Thicker walls provide better mechanical strength but may reduce thermal conductivity. Balance the two based on your needs.

Mechanical Strength

- High-purity alumina provides superior mechanical strength, which is crucial in high-stress environments. Evaluate the load-bearing requirements of your application.

Thermal Shock Resistance

- If your application involves rapid temperature changes, select an alumina tube with high thermal shock resistance to prevent cracking or breaking.

Electrical Insulation

- Alumina is an excellent electrical insulator. If your application involves electrical components or requires insulation, this property is essential.

Corrosion and Wear Resistance

- Alumina is highly resistant to corrosion and wear, making it ideal for use in harsh environments or with aggressive chemicals.

Application Environment

- Vacuum or Inert Atmosphere: Alumina tubes perform well in these conditions.

- Oxidizing Atmosphere: Ensure the alumina grade can withstand exposure without degrading.

Customization

- For specialized applications, consider if you need customized dimensions, shapes, or properties. Many manufacturers offer tailored solutions to meet specific requirements.

Cost Considerations

- Higher purity and specialized alumina tubes can be expensive. Balance performance needs with budget constraints to choose the most cost-effective option.

Read also: Alumina Tubes: Properties, Uses, and Maintenance Tips

Supplier Reliability

- Choose a reputable supplier with a track record of providing high-quality alumina products. Consider suppliers with strong customer support and the ability to meet your specifications consistently.

Conclusion:

By carefully evaluating these factors, you can select the right alumina tube that meets your specific application needs, ensuring optimal performance and longevity.

M-Kube Enterprise is a USA company catering customized laboratory products, laboratory consumables, and laboratory solutions in India, Australia, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.