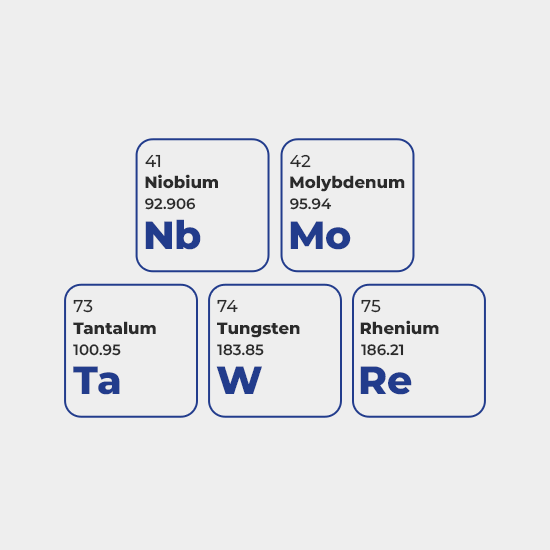

Selecting the right refractory metal for your specific application involves considering several key factors to ensure

that the material meets the required performance and longevity criteria. Refractory metals, such as tungsten,

molybdenum, tantalum, niobium, and rhenium, have unique properties and applications. Here’s a guide to help you choose the appropriate refractory metal:

- Temperature Requirements:

- Determine the maximum and minimum operating temperatures for your application. Different refractory metals

have different temperature limits, and you should choose one that can withstand the temperature range

required.

- Chemical Compatibility:

- Consider the chemical environment in which the material will be used. Some refractory metals are more resistant

to specific chemicals and corrosive agents than others. Choose a metal that is compatible with your

application’s chemicals.

- Mechanical Properties:

- Evaluate the mechanical properties such as strength, ductility, and hardness. Different refractory metals have

varying mechanical characteristics, which may be critical for your specific application.

- Thermal Conductivity:

- Depending on your application, you may need a refractory metal with good thermal conductivity or one with low

thermal conductivity. Consider the thermal properties that align with your needs.

- Electrical Conductivity:

- If electrical conductivity is important for your application, select a refractory metal that offers the required

electrical conductivity.

- Fabrication and Machinability:

- Consider the ease of machining and fabricating the refractory metal. Some metals are easier to work with than

others. Determine if the material can be easily shaped, cut, or formed to meet your needs.

- Availability and Cost:

- Evaluate the availability and cost of the refractory metal. Some metals may be more readily available and

cost-effective than others, depending on your location and the quantity you need.

- Specific Applications:

- Refractory metals are often chosen based on their specific applications. For example:

- Tungsten is often used in high-temperature and radiation-shielding applications.

- Molybdenum is used in the aerospace and electronics industries.

- Tantalum is known for its corrosion resistance and is used in chemical processing.

- Niobium is used in superconductors and the medical field.

- Rhenium is employed in aerospace and high-temperature applications.

- Longevity and Durability:

- Consider the expected service life and durability of the refractory metal. Some materials are more resistant to

wear and degradation than others, which may be crucial for long-term use.

- Regulatory Compliance:

- Ensure that the selected refractory metal complies with any relevant regulations and safety standards for your

industry.

- Consultation:

- If you are uncertain about which refractory metal to choose, consider consulting with a materials engineer or a

specialist who can provide guidance based on your specific application requirements.

It’s important to thoroughly analyze all these factors and conduct a cost-benefit analysis to select the most suitable

refractory metal for your particular needs. The choice should be based on a careful assessment of the specific demands of your application, as each refractory metal has its unique set of properties and limitations.

Conclusion:

Choosing the right refractory metal depends on your specific application requirements such as temperature resistance, corrosion resistance, mechanical strength, and conductivity. By carefully evaluating these factors, you can select the metal that offers optimal performance, durability, and cost-effectiveness for your project. Whether for aerospace, electronics, or industrial use, understanding the unique properties of each refractory metal ensures reliable and efficient results.

We are a USA company catering products and solutions in the USA, Australia, New Zealand, Singapore, Malaysia, India, South Korea and Vietnam.