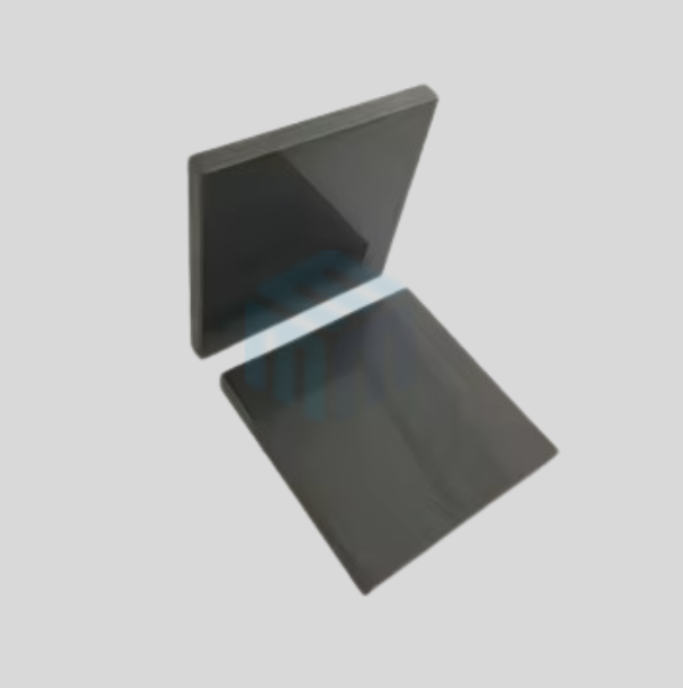

Silicon carbide (SiC) polished sheets are advanced ceramic materials engineered to perform under extreme thermal and mechanical stress. Their unique combination of hardness, thermal conductivity, and chemical resistance makes them indispensable in high-temperature environments across various industries.

About SiC Polished Sheets

SiC polished sheets are ceramic plates composed of high-purity silicon carbide and refined through a precision polishing process to achieve a low surface roughness. These sheets are exceptionally hard (second only to diamond), thermally stable up to 1600°C, and highly resistant to wear and corrosion. The polished finish enhances their effectiveness in precision optical and electronic applications.

At M-Kube, we offer high-performance ceramic and analytical testing components, including SiC, alumina, and zirconia substrates for high-temperature and corrosive applications.

Uses of SiC Polished Sheets

SiC polished sheets serve critical roles in industries that require both structural resilience and precision performance:

- Semiconductor and Electronics Manufacturing

- Serve as substrates or carrier plates during wafer processing and high-temperature annealing steps

- Ideal for ion implantation and vacuum deposition due to their thermal conductivity and chemical inertness

- High-Temperature Furnaces

- Used as protective linings, support plates, or setters in sintering, brazing, and metal treatment furnaces

- Withstand thermal cycling and rapid temperature changes without warping or degrading

- Thermal Management Systems

- Their high thermal conductivity (approx. 120 W/m·K) allows them to efficiently dissipate heat in power electronics and laser systems

- Optical and Laser Applications

- Polished SiC surfaces are suitable for mirrors, mounts, and optical backings in high-power laser setups

- Corrosive Chemical Environments

- Resistant to acids, alkalis, and harsh chemicals, making them valuable in chemical vapor deposition (CVD) and aggressive processing conditions

Looking for thermal support components? Explore our Ceramic Sheets and Crucibles. Read also: Silicon carbide: Properties, Uses, and Maintenance Tips

Conclusion

SiC polished sheets offer an unmatched combination of strength, heat resistance, and chemical stability. Their polished finish makes them ideal for precise, high-temperature applications in industries such as semiconductors, optics, and metallurgy. For operations requiring durability and thermal management under extreme conditions, SiC sheets are the smart choice.